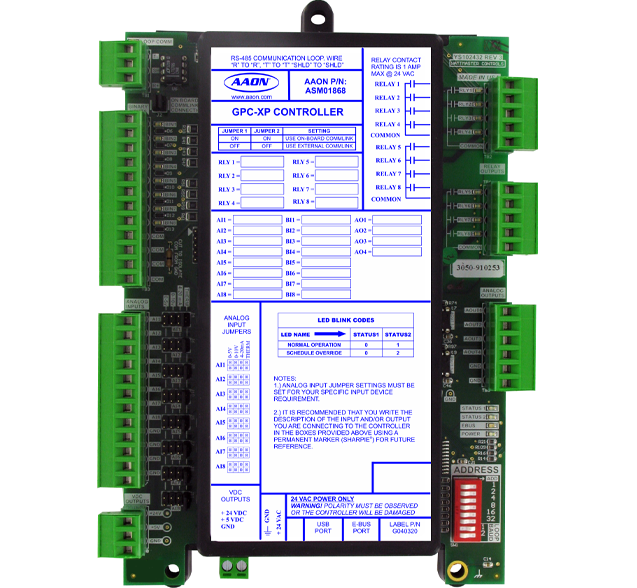

Unit Controllers

Our unit controllers provide field proven sequences of operation tailored for AAON equipment needs. Embedded applications allow simple field configuration instead of complex programming. Our controllers go through rigorous testing at assembly and end of line at our facilities to ensure low failure rate and high customer satisfaction. They are designed with fixed inputs and outputs for ease of use. Additional functionality and I/O are accomplished with the use of expansion modules, refrigeration modules, and other end devices.

SPECIFICATIONS

-

Applications

Unit Controllers come with embedded applications that can be field configured based on need.

- Constant Air Volume (CAV) is a simple application that delivers conditioned air into a single space using space or return air temperature

- Variable Air Volume (VAV) allows precise temperature control based on loads in multiple occupied spaces while reducing energy usage

- Single Zone VAV (SZVAV) allows precise temperature control based on the load in the space while reducing energy usage and noise

- Make-Up Air (MUA) is generally designed for 100% Outdoor Air applications such as Dedicated Outdoor Air Systems (DOAS)

- Space Temperature Control of High Percentage Outdoor Air Units is a dual application that operates as a CAV and, when the space is satisfied, it supplies conditioned outside air

- Zoned Systems is a voting system that allows the AHU to respond to heating and cooling demands from the associated zones

- Dehumidification is accomplished using hot gas reheat, return air bypass, and/or unit heat (i.e., electric, hot water)

-

Quality

Controls quality and reliability are crucial to a positive ownership experience. AAON unit controllers’ low failure rate is directly attributed to our quality process:

- UL certified to ensure industry safety criteria are met

- During the design stage, durability is assessed through our environmental and electrical testing

- Controllers go through continued testing in all phases of production to ensure integrity of the product

To complement our quality process, our support teams provide feedback integral for continual improvement.

-

Standard Features

Our controllers are designed with a baseline sequence of operations and only require additional modules as extra features are needed.

For instance:

- On-board BACnet

- Multiple stages of heating and cooling.

- Configurable relays

- Field selectable controlling temperature sensor

- Supply Air Reset

- Economizer Control

- Indoor Air Quality

- Building Pressure Relief Control

- Trend logging

-

Sustainability

In concert with AAON AHU, our unit controllers provide a more sustainable system when utilizing the following capabilities.

- Economizer

- VAV

- Modulating Compressors

- Hot Gas Reheat

- Heat Wheel

- Condenser Fan Optimization

-

Health/IAQ

Building design codes require a minimum volume of outdoor air based on the design occupancy. Our unit controllers exceed design codes to create a favorable environment by supplying fresh air into the space to keep the CO2 at an acceptable level.

Unit Controllers come with embedded applications that can be field configured based on need.

- Constant Air Volume (CAV) is a simple application that delivers conditioned air into a single space using space or return air temperature

- Variable Air Volume (VAV) allows precise temperature control based on loads in multiple occupied spaces while reducing energy usage

- Single Zone VAV (SZVAV) allows precise temperature control based on the load in the space while reducing energy usage and noise

- Make-Up Air (MUA) is generally designed for 100% Outdoor Air applications such as Dedicated Outdoor Air Systems (DOAS)

- Space Temperature Control of High Percentage Outdoor Air Units is a dual application that operates as a CAV and, when the space is satisfied, it supplies conditioned outside air

- Zoned Systems is a voting system that allows the AHU to respond to heating and cooling demands from the associated zones

- Dehumidification is accomplished using hot gas reheat, return air bypass, and/or unit heat (i.e., electric, hot water)

Controls quality and reliability are crucial to a positive ownership experience. AAON unit controllers’ low failure rate is directly attributed to our quality process:

- UL certified to ensure industry safety criteria are met

- During the design stage, durability is assessed through our environmental and electrical testing

- Controllers go through continued testing in all phases of production to ensure integrity of the product

To complement our quality process, our support teams provide feedback integral for continual improvement.

Our controllers are designed with a baseline sequence of operations and only require additional modules as extra features are needed.

For instance:

- On-board BACnet

- Multiple stages of heating and cooling.

- Configurable relays

- Field selectable controlling temperature sensor

- Supply Air Reset

- Economizer Control

- Indoor Air Quality

- Building Pressure Relief Control

- Trend logging

- Economizer

- VAV

- Modulating Compressors

- Hot Gas Reheat

- Heat Wheel

- Condenser Fan Optimization

Building design codes require a minimum volume of outdoor air based on the design occupancy. Our unit controllers exceed design codes to create a favorable environment by supplying fresh air into the space to keep the CO2 at an acceptable level.