Manufacturing

Manage the energy efficiency of your manufacturing facility with greater ease - because there’s no time for downtime.

Manufacturers keep the economy moving forward. With AAON, manufacturing facilities can strike the right balance between energy efficiency and cost containment with HVAC products that provide unparalleled lifetime value.

MANUFACTURING SOLUTIONS

-

About Manufacturing Facilities

Manufacturing buildings often require specialized HVAC systems to ensure optimal indoor air quality and temperature control to maintain the safety and productivity of the manufacturing process. Ranging from small-scale workshops to large industrial manufacturing facilities where products like food, electronics, automobiles, and chemicals are produced, assembled, or processed using machinery, labor, or a combination of both.

-

Manufacturing Considerations

When implementing HVAC solutions in a manufacturing facility, here are some key considerations to keep in mind:

Process requirements

Manufacturing buildings have varying process requirements that affect the temperature and humidity levels of the facility. When designing an HVAC system for a manufacturing building, it is important to consider these process requirements and design a system that can meet them efficiently. Varying temperatures from machines running and the amount of people working in a space can affect the performance of the unit.

Air quality

Manufacturing processes often generate pollutants and particles that can affect the air quality of the facility. HVAC systems should be designed to remove these pollutants and provide clean air for the workers. AAON units have AMCA certified economizers that can provide up to 100% outside air, providing fresh air for the workers in the building. Utilizing high efficiency filtration effectively removes particles from the air supplied to the space.

Energy efficiency

Manufacturing buildings consume a large amount of energy, and HVAC systems can be a significant contributor to this energy consumption. Energy-efficient HVAC systems can reduce energy costs and improve the sustainability of the facility. Modulating supply fans, variable speed compressors, and energy recovery wheels are great options to use in the system for reducing the amount of energy the unit consumes.

Serviceability

Manufacturing facilities often operate 24/7, which puts a strain on HVAC systems. HVAC systems should be designed with maintenance and serviceability in mind to minimize downtime and ensure the longevity of the equipment. Lockable hinged service doors provide quick access to critical components in the unit without affecting operation. Color-coded wiring diagrams allow for quick troubleshooting of electrical issues.

Building design

The layout, design and size of the manufacturing building can affect HVAC system requirements. It is important to consider the layout of the building and how air will flow throughout the facility to ensure efficient operation of the HVAC system. -

Manufacturing Solutions

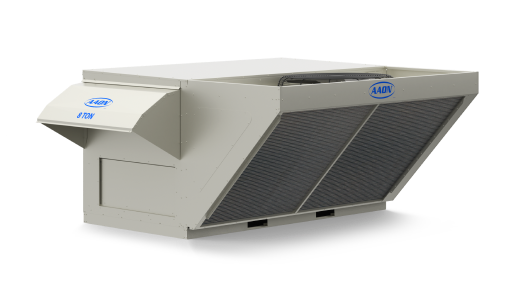

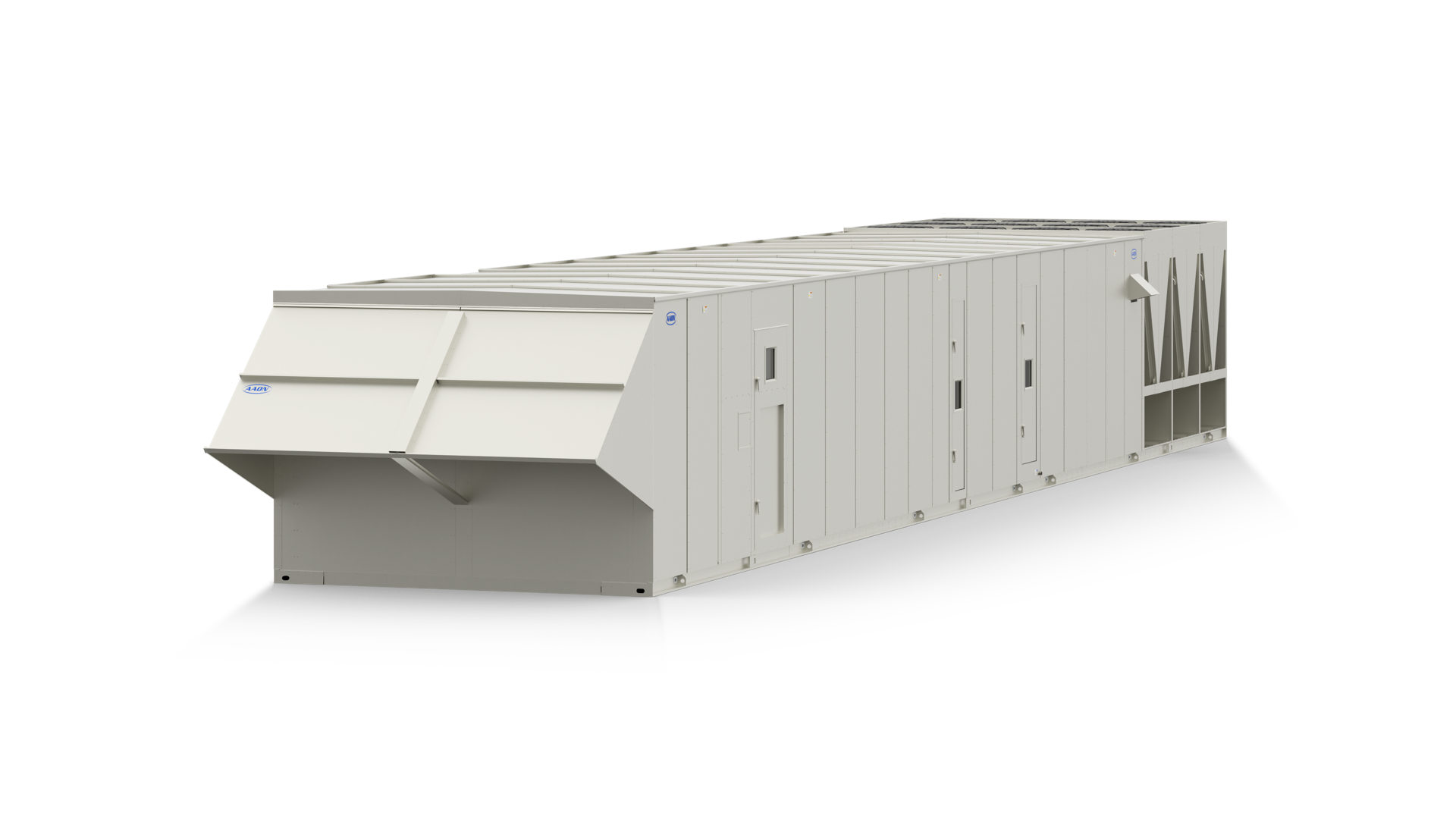

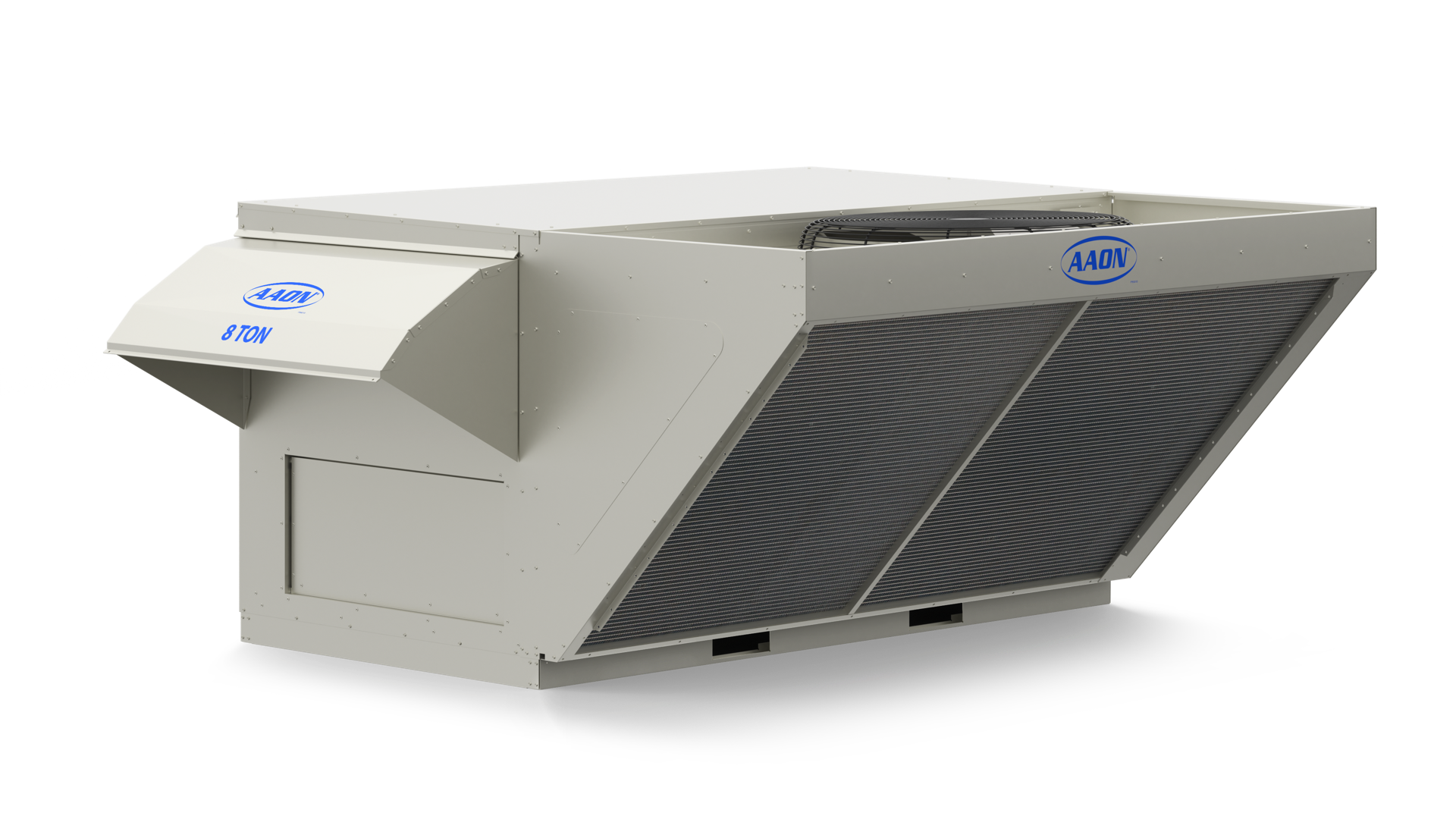

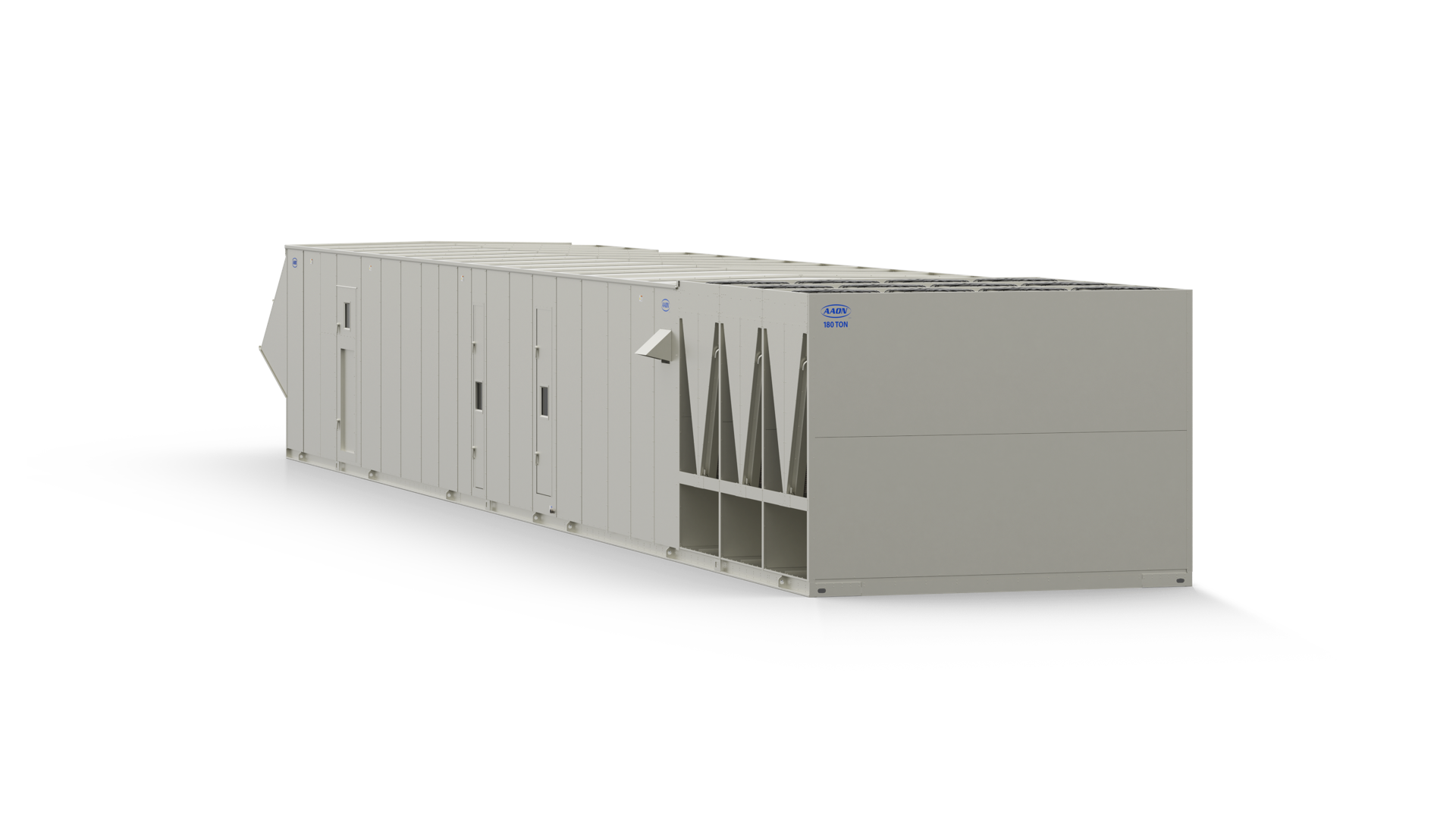

Several HVAC products recommended for manufacturing buildings include:

- Dedicated Outdoor Air System Units

- Variable Air Volume or Single Zone VAV

- Air-Source and Water-Source Heat Pump

In general, HVAC systems must be designed to operate with greater efficiency, using less energy, and delivering cost savings to manufacturing facilities. High-efficiency HVAC systems can help maintain optimal indoor air quality while reducing energy costs associated with heating and cooling.

Manufacturing buildings often require specialized HVAC systems to ensure optimal indoor air quality and temperature control to maintain the safety and productivity of the manufacturing process. Ranging from small-scale workshops to large industrial manufacturing facilities where products like food, electronics, automobiles, and chemicals are produced, assembled, or processed using machinery, labor, or a combination of both.

When implementing HVAC solutions in a manufacturing facility, here are some key considerations to keep in mind:

Process requirements

Manufacturing buildings have varying process requirements that affect the temperature and humidity levels of the facility. When designing an HVAC system for a manufacturing building, it is important to consider these process requirements and design a system that can meet them efficiently. Varying temperatures from machines running and the amount of people working in a space can affect the performance of the unit.

Air quality

Manufacturing processes often generate pollutants and particles that can affect the air quality of the facility. HVAC systems should be designed to remove these pollutants and provide clean air for the workers. AAON units have AMCA certified economizers that can provide up to 100% outside air, providing fresh air for the workers in the building. Utilizing high efficiency filtration effectively removes particles from the air supplied to the space.

Energy efficiency

Manufacturing buildings consume a large amount of energy, and HVAC systems can be a significant contributor to this energy consumption. Energy-efficient HVAC systems can reduce energy costs and improve the sustainability of the facility. Modulating supply fans, variable speed compressors, and energy recovery wheels are great options to use in the system for reducing the amount of energy the unit consumes.

Serviceability

Manufacturing facilities often operate 24/7, which puts a strain on HVAC systems. HVAC systems should be designed with maintenance and serviceability in mind to minimize downtime and ensure the longevity of the equipment. Lockable hinged service doors provide quick access to critical components in the unit without affecting operation. Color-coded wiring diagrams allow for quick troubleshooting of electrical issues.

Building design

The layout, design and size of the manufacturing building can affect HVAC system requirements. It is important to consider the layout of the building and how air will flow throughout the facility to ensure efficient operation of the HVAC system.

- Dedicated Outdoor Air System Units

- Variable Air Volume or Single Zone VAV

- Air-Source and Water-Source Heat Pump

In general, HVAC systems must be designed to operate with greater efficiency, using less energy, and delivering cost savings to manufacturing facilities. High-efficiency HVAC systems can help maintain optimal indoor air quality while reducing energy costs associated with heating and cooling.

Why AAON for Manufacturing?

AAON stops at nothing to design the very best.

All AAON products are highly configurable and designed to optimize your exact environment. With high quality features, our systems set the industry standard for long-lasting quality.

AAON equipment is easy to access and convenient to work on.

Our products make it simple for technicians to service our units efficiently and affordably. Unique features like color-coded wiring and full height stainless steel door hinges are designed with serviceability in mind.

AAON equipment is renowned for reliability.

Our products are tested for all functions and receive a unit-specific report before they leave the factory. Choose cutting-edge engineering that pushes the boundaries of what's possible in virtually any climate and application.

Related Products

Dare us to exceed expectations.

Regardless of the challenge, AAON has the capabilities to fulfill project requirements and deliver long-term value to customers. Contact an AAON Representative to learn how our products serve as your solutions.