PACKAGED ROOFTOP UNITS

The world's best RTU. Built just for you.

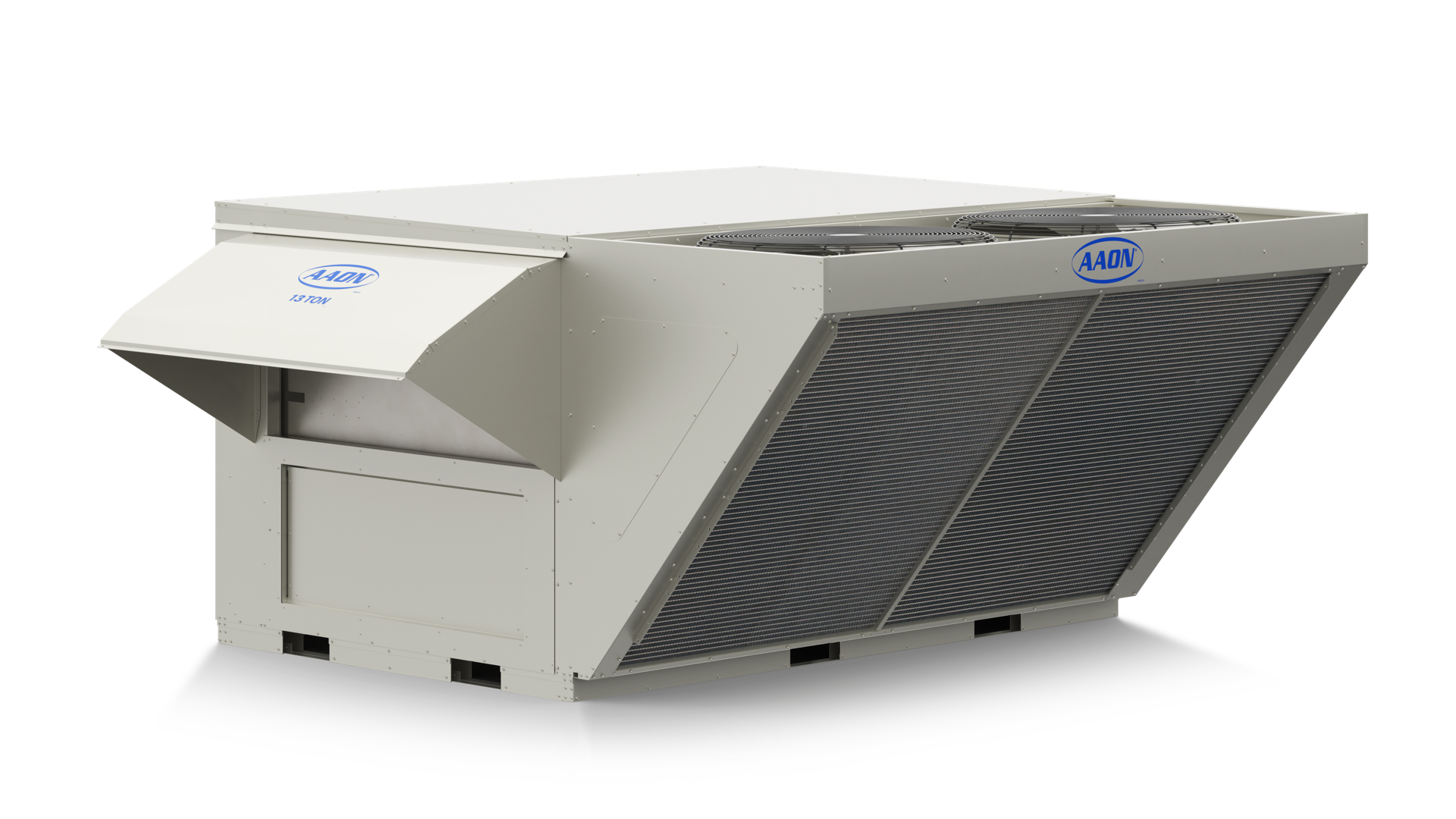

Widely considered the industry's gold standard for performance, AAON packaged rooftop units offer superior efficiency, reliability, and longevity.

Better yet, every AAON system is configured to meet your specific needs for outstanding results for years to come.

PRODUCT OVERVIEW

-

Overview

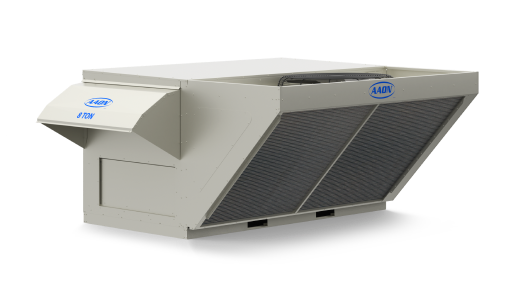

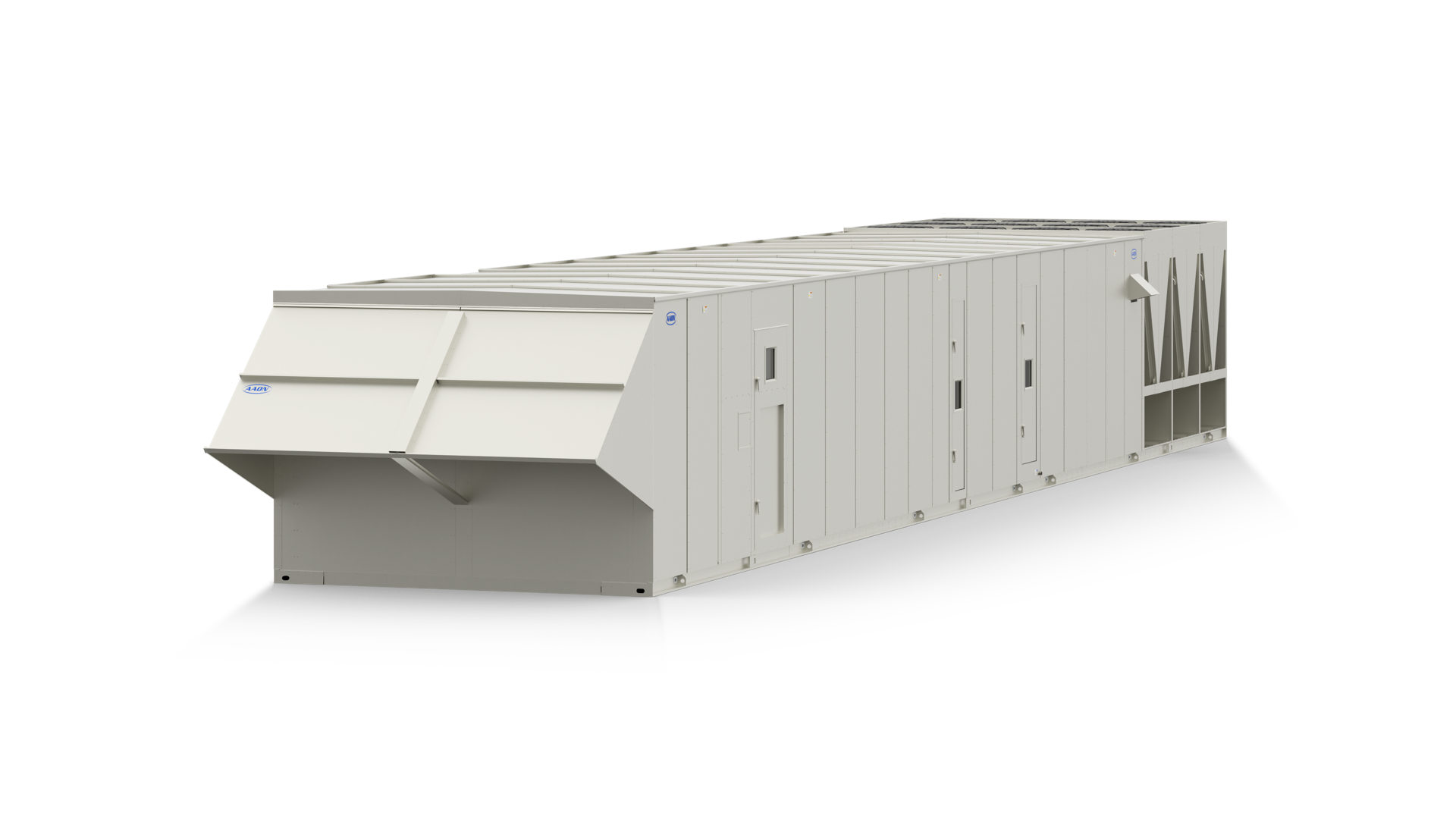

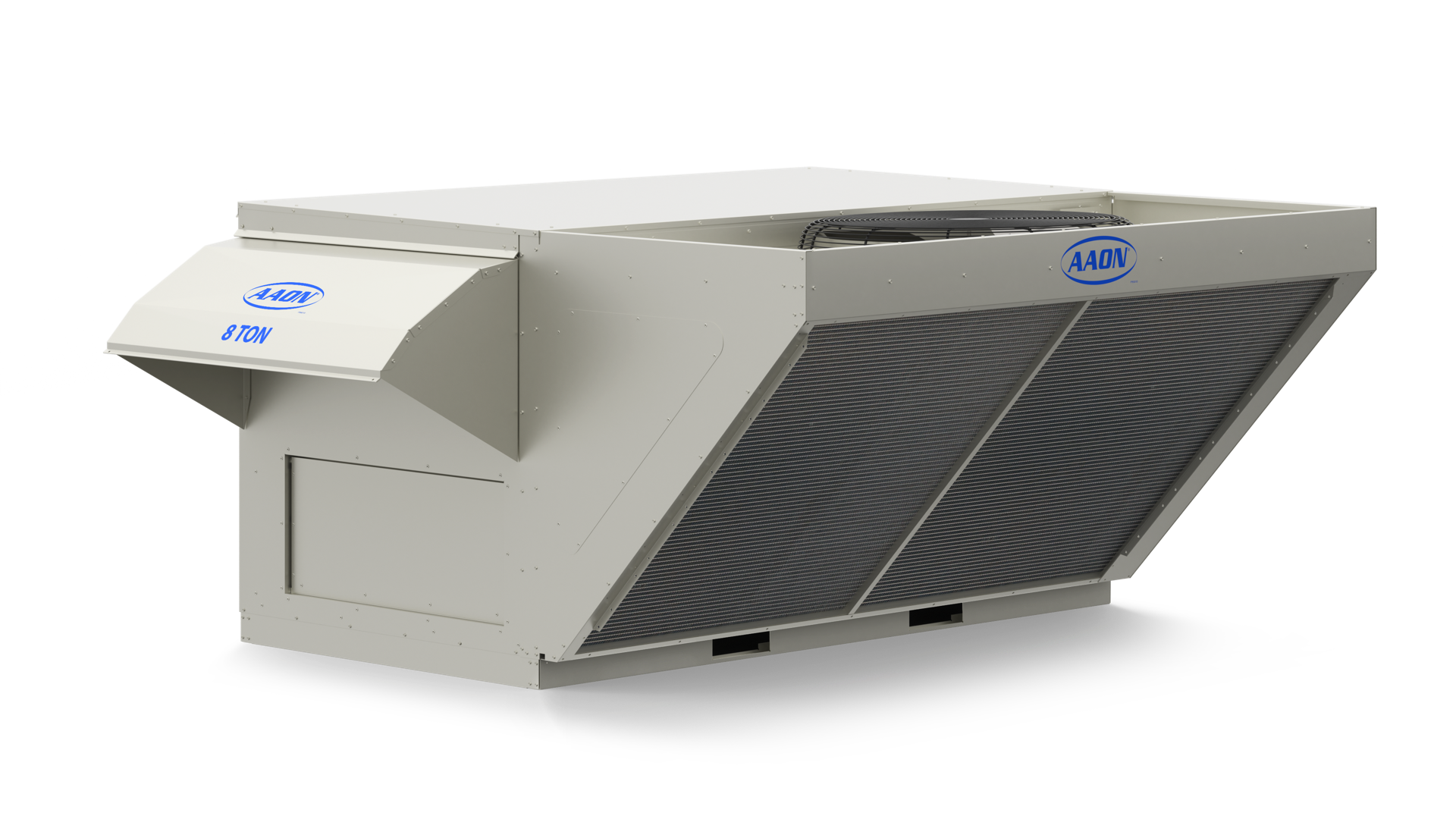

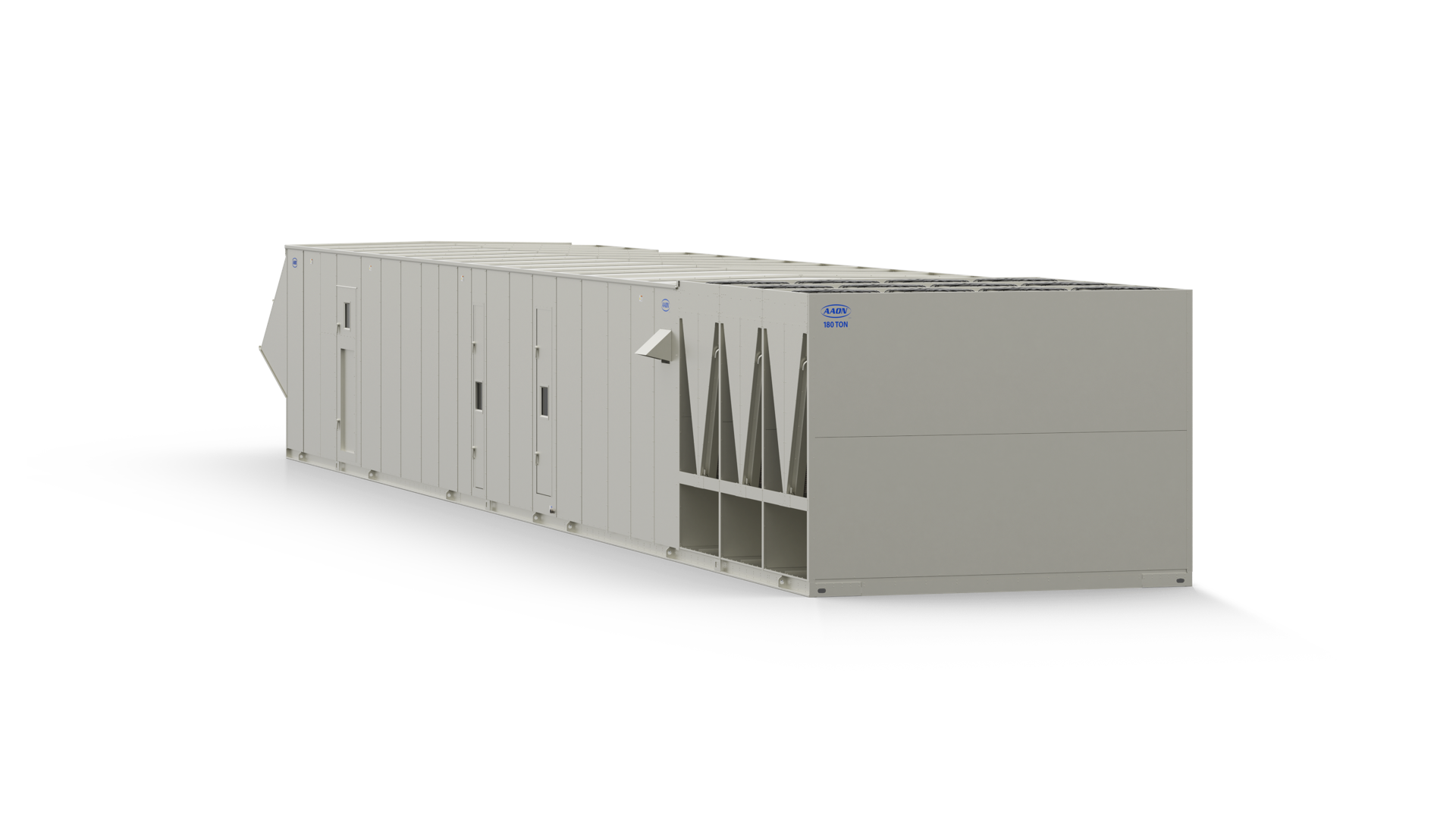

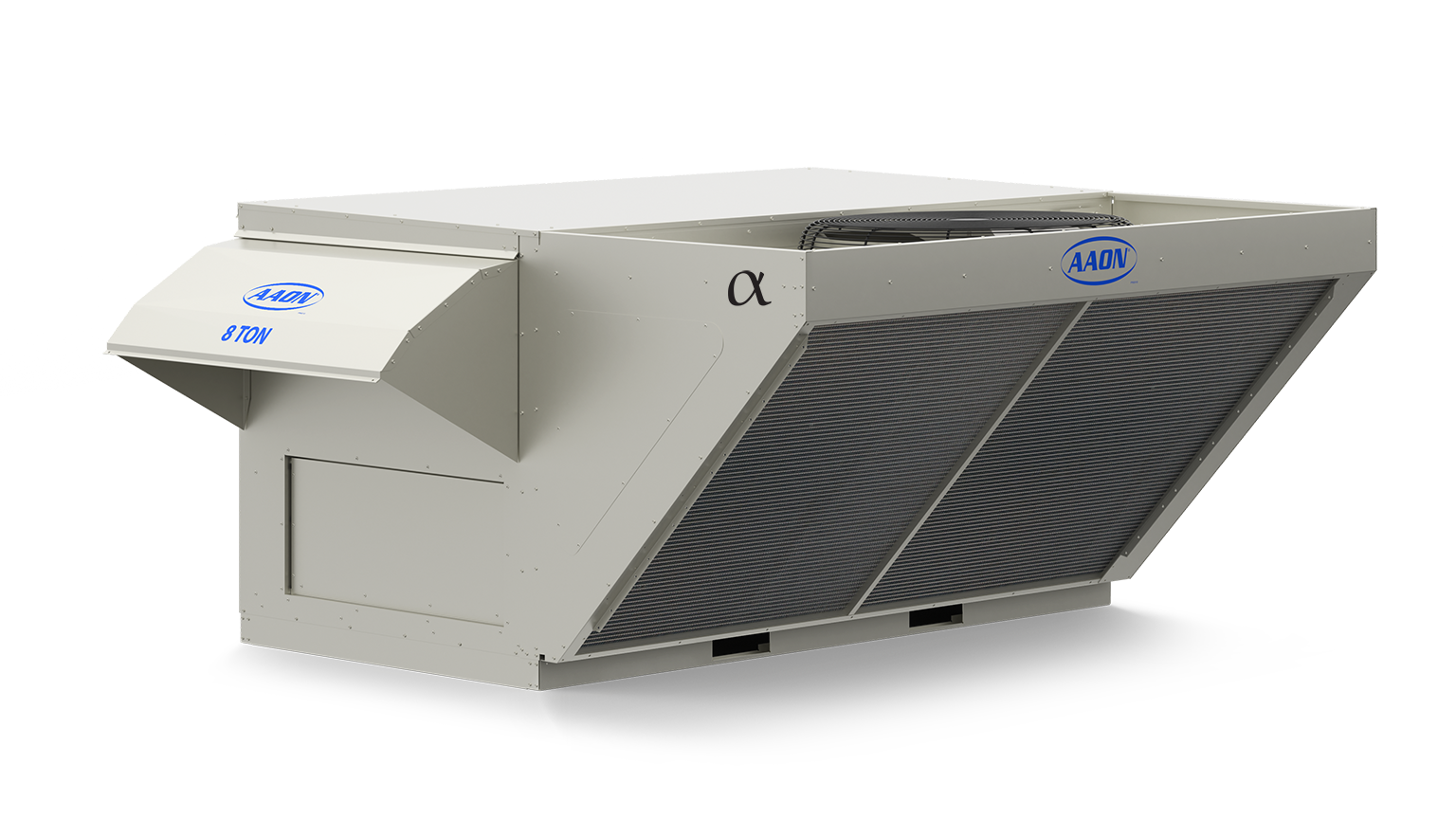

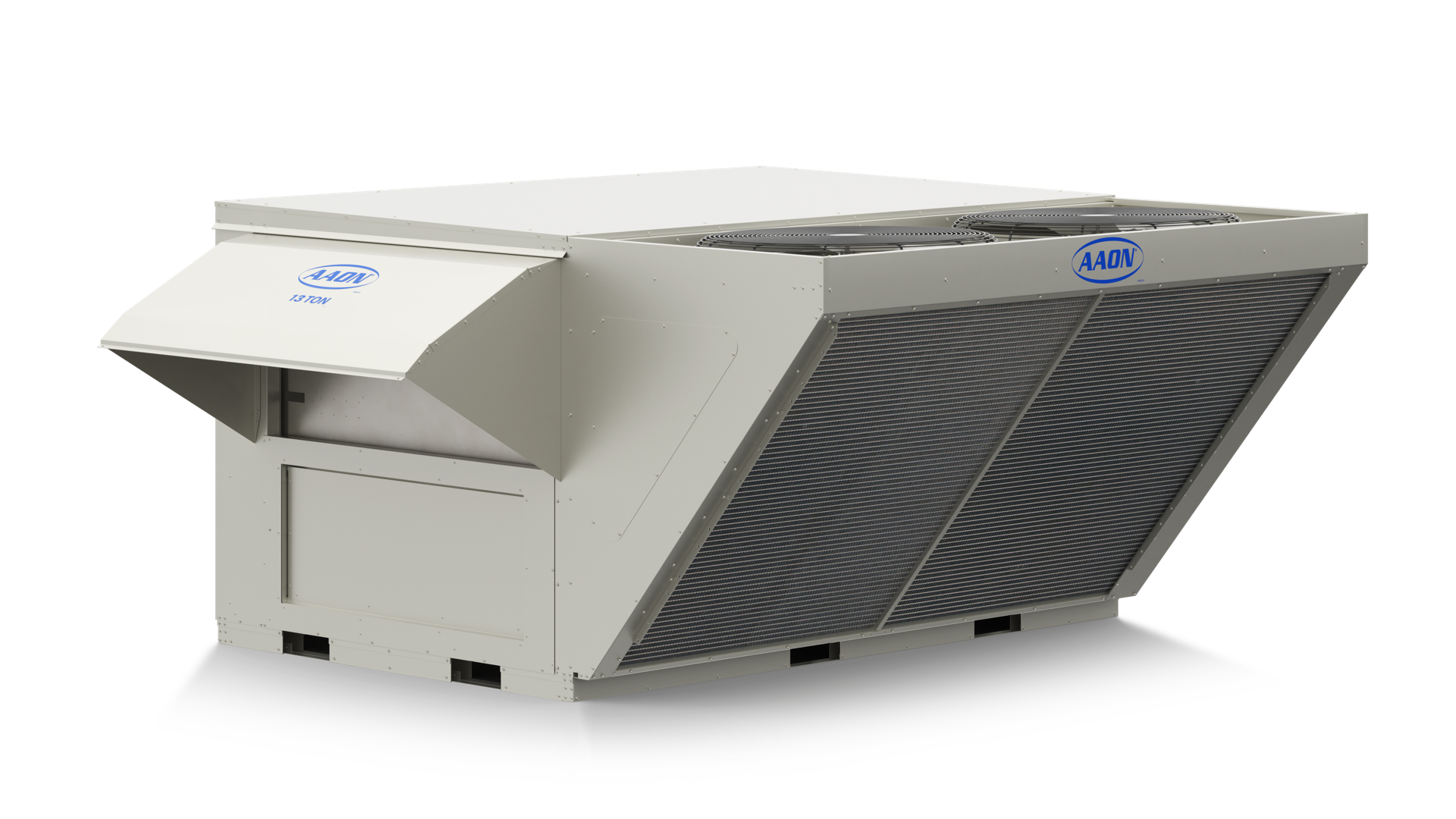

AAON packaged rooftop units (RTUs) represent the best the industry has to offer. RTUs contain all of the necessary components for heating and cooling, including a compressor, condenser, evaporator, and air-handling unit. The unit is designed to be self-contained, meaning that all of the components are housed in a single, compact unit that can be easily installed on the roof of a building.

Packaged rooftop units are commonly used in commercial buildings because they are efficient, reliable, and easy to maintain. AAON rooftop units are designed to be weather-resistant and durable, making them suitable for use in a wide range of climates and environments.

-

High-Level Specifications

AAON RTUs provide the ultimate in performance, optimization, and long-term value. With industry-leading quality, you can expect superior energy savings, accessible maintenance and reliability.

Key features and specifications:

- Multiple configurations are available from air-cooled or water-cooled condensers to chilled water coils, DX air handling, air-source, water-source, or geothermal heat pump options. Standard microchannel condenser coils are durable, more efficient, lighter, and use less refrigerant than traditional fin and tube condenser coils.

- Lockable hinged doors provide easy access to all sections of the unit for hassle-free servicing.

- AHRI Certified with most of our equipment meeting AHRI 210/240 or AHRI 340/360 depending on unit size.

- AMCA-certified and labeled low leakage economizer dampers with optional economizer fault detection and diagnostics.

- Air-Cooled EER Efficiency Values from 12.1 to 14.8, available in 2 -240 tons.

-

Considerations

When it comes to selecting a packaged rooftop unit, there are a number of things consider, including:

- Size and capacity: Find the perfect fit. The size and capacity of the RTU should be selected based on the building's size and cooling/heating requirements. An RTU that is too small for the building will struggle to cool or heat the building effectively, while an oversized RTU will lead to higher energy bills and unnecessary wear and tear.

- Energy efficiency: Be good to your bottom-line and the environment. Look for an RTU that is AHRI certified with high-efficiency ratings, as it will use less energy and cost less to operate. In addition to saving money on energy bills, an energy-efficient RTU also has a lower carbon footprint, which is better for the environment.

- Budget and upfront cost: Consider initial cost and long-term savings. RTUs are a necessary investment, so it's important to not only consider the upfront cost but the long-term savings and benefits of an energy-efficient and reliable RTU.

-

Testing & Quality Control

We’re not just about saying we’re the best. We’re about proving it to ourselves and the industry with thorough testing, robust quality control measures and certifications.

- Tested to stand the test of time. With our very own state of the art research & development lab we can conduct research, product development, and testing of new and existing products. Our R&D facility allows us to test to AHRI standards as well as more extreme conditions than certification testing standards or our competitors can perform.

- Committed to quality. Our dedication to our customers, compliance with regulatory requirements, and commitment to stakeholders are the greatest incentives to our quality goals. Every product goes through thorough inspection, testing and final inspection.

- Certifiably cool. Many of our products meet certification standards of the governing body for the HVAC industry, the Air-Conditioning, Heating, and Refrigeration Institute (AHRI)

- Tested to stand the test of time. With our very own state of the art research & development lab we can conduct research, product development, and testing of new and existing products. Our R&D facility allows us to test to AHRI standards as well as more extreme conditions than certification testing standards or our competitors can perform.

-

Serviceability

AAON units are designed with features that make it easier to save time and money.

- Designed with access in mind. AAON units are designed with full length hinge doors as opposed to removable panels with sheet metal screws that can be easily lost or stripped out over time.

- Proactive troubleshooting. Troubleshooting wiring is a common first step in identifying issues. AAON provides full color complete wiring diagrams laminated inside each unit. No more black and white diagrams that don't help diagnose the problem.

- We're about getting the job done. AAON provides every technician comprehensive support with a dedicated Service & Tech Support team.

-

Warranty

Many competitors provide prorated warranties, only offering discounts for a replacement. With AAON, you can expect a non-prorated warranty for select products which means full replacement of a unit within warranty.

- For RN series units, the Limited Warranty is effective for 12 months from the date of original installation, or 18 months from the date of original shipment from the factory, whichever occurs first.

- The AAON standard compressor warranty is 5 years. Customers can purchase an extended warranty for the entire unit or just compressors up to 10 years.

- The AAON Aluminized Gas Heat exchangers carry a 15 year non-prorated warranty, and the Stainless Steel Gas Heat exchangers have a 25 year non-prorated warranty.

AAON packaged rooftop units (RTUs) represent the best the industry has to offer. RTUs contain all of the necessary components for heating and cooling, including a compressor, condenser, evaporator, and air-handling unit. The unit is designed to be self-contained, meaning that all of the components are housed in a single, compact unit that can be easily installed on the roof of a building.

Packaged rooftop units are commonly used in commercial buildings because they are efficient, reliable, and easy to maintain. AAON rooftop units are designed to be weather-resistant and durable, making them suitable for use in a wide range of climates and environments.

AAON RTUs provide the ultimate in performance, optimization, and long-term value. With industry-leading quality, you can expect superior energy savings, accessible maintenance and reliability.

Key features and specifications:- Multiple configurations are available from air-cooled or water-cooled condensers to chilled water coils, DX air handling, air-source, water-source, or geothermal heat pump options. Standard microchannel condenser coils are durable, more efficient, lighter, and use less refrigerant than traditional fin and tube condenser coils.

- Lockable hinged doors provide easy access to all sections of the unit for hassle-free servicing.

- AHRI Certified with most of our equipment meeting AHRI 210/240 or AHRI 340/360 depending on unit size.

- AMCA-certified and labeled low leakage economizer dampers with optional economizer fault detection and diagnostics.

- Air-Cooled EER Efficiency Values from 12.1 to 14.8, available in 2 -240 tons.

When it comes to selecting a packaged rooftop unit, there are a number of things consider, including:

- Size and capacity: Find the perfect fit. The size and capacity of the RTU should be selected based on the building's size and cooling/heating requirements. An RTU that is too small for the building will struggle to cool or heat the building effectively, while an oversized RTU will lead to higher energy bills and unnecessary wear and tear.

- Energy efficiency: Be good to your bottom-line and the environment. Look for an RTU that is AHRI certified with high-efficiency ratings, as it will use less energy and cost less to operate. In addition to saving money on energy bills, an energy-efficient RTU also has a lower carbon footprint, which is better for the environment.

- Budget and upfront cost: Consider initial cost and long-term savings. RTUs are a necessary investment, so it's important to not only consider the upfront cost but the long-term savings and benefits of an energy-efficient and reliable RTU.

We’re not just about saying we’re the best. We’re about proving it to ourselves and the industry with thorough testing, robust quality control measures and certifications.

- Tested to stand the test of time. With our very own state of the art research & development lab we can conduct research, product development, and testing of new and existing products. Our R&D facility allows us to test to AHRI standards as well as more extreme conditions than certification testing standards or our competitors can perform.

- Committed to quality. Our dedication to our customers, compliance with regulatory requirements, and commitment to stakeholders are the greatest incentives to our quality goals. Every product goes through thorough inspection, testing and final inspection.

- Certifiably cool. Many of our products meet certification standards of the governing body for the HVAC industry, the Air-Conditioning, Heating, and Refrigeration Institute (AHRI)

AAON units are designed with features that make it easier to save time and money.

- Designed with access in mind. AAON units are designed with full length hinge doors as opposed to removable panels with sheet metal screws that can be easily lost or stripped out over time.

- Proactive troubleshooting. Troubleshooting wiring is a common first step in identifying issues. AAON provides full color complete wiring diagrams laminated inside each unit. No more black and white diagrams that don't help diagnose the problem.

- We're about getting the job done. AAON provides every technician comprehensive support with a dedicated Service & Tech Support team.

Many competitors provide prorated warranties, only offering discounts for a replacement. With AAON, you can expect a non-prorated warranty for select products which means full replacement of a unit within warranty.

- For RN series units, the Limited Warranty is effective for 12 months from the date of original installation, or 18 months from the date of original shipment from the factory, whichever occurs first.

- The AAON standard compressor warranty is 5 years. Customers can purchase an extended warranty for the entire unit or just compressors up to 10 years.

- The AAON Aluminized Gas Heat exchangers carry a 15 year non-prorated warranty, and the Stainless Steel Gas Heat exchangers have a 25 year non-prorated warranty.

Related Products

Engineered to Optimize

All AAON HVAC products are highly configurable and designed to optimize your exact environment with cutting-edge engineering to push the boundaries in virtually any setting.

Industry Leading Quality

AAON stops at nothing to design the very best. Our systems set the industry standard for longevity and low cost of ownership.

Ease of Maintenance

AAON equipment is easy to access and convenient to work on. Our award-winning cabinet designs make it simple for technicians to service our units efficiently and affordably.

Verified Performance

AAON HVAC units offer easy start-up and renowned reliability. Our products are tested for all functions and receive a unit-specific report before they leave the factory.

Dare us to exceed expectations.

Regardless of the challenge, AAON has the capabilities to fulfill project requirements and deliver long-term value to customers. Contact an AAON Representative to learn how our products serve as your solutions.