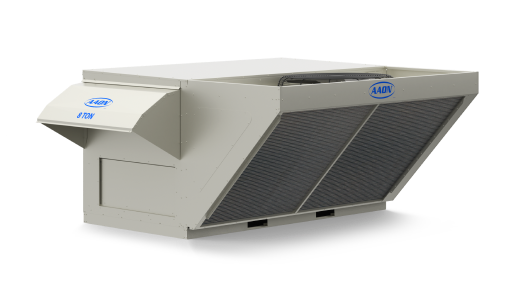

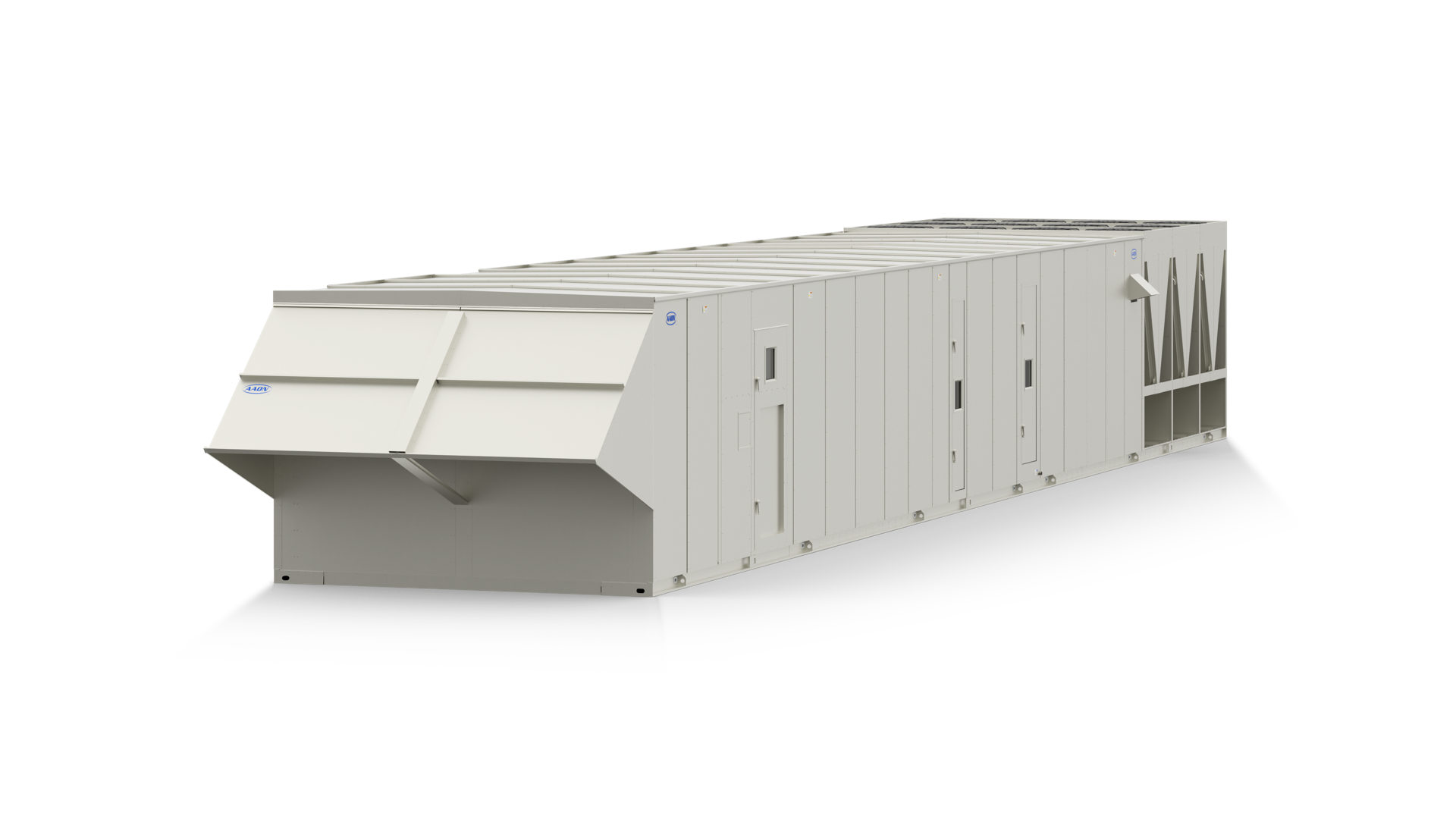

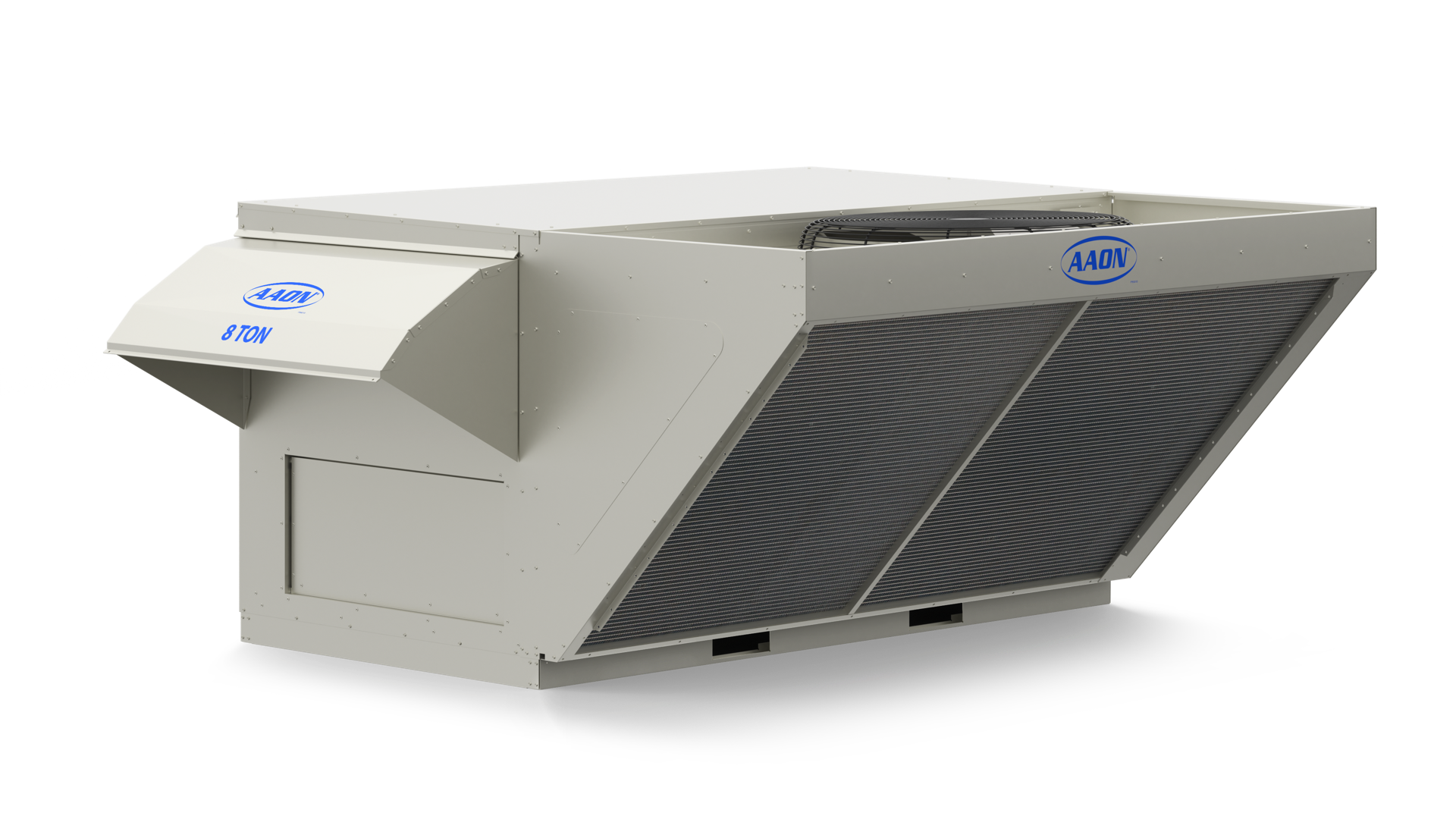

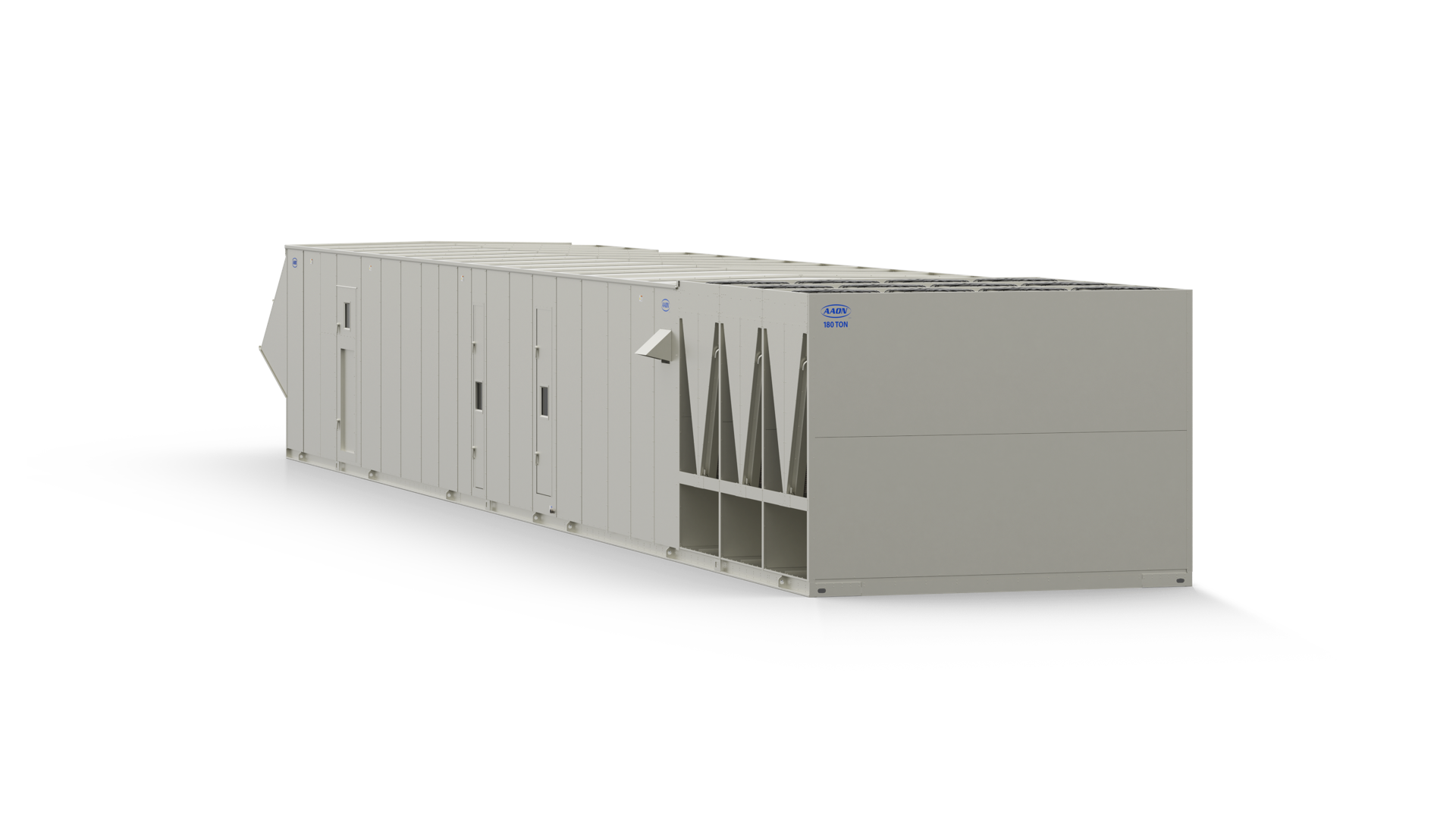

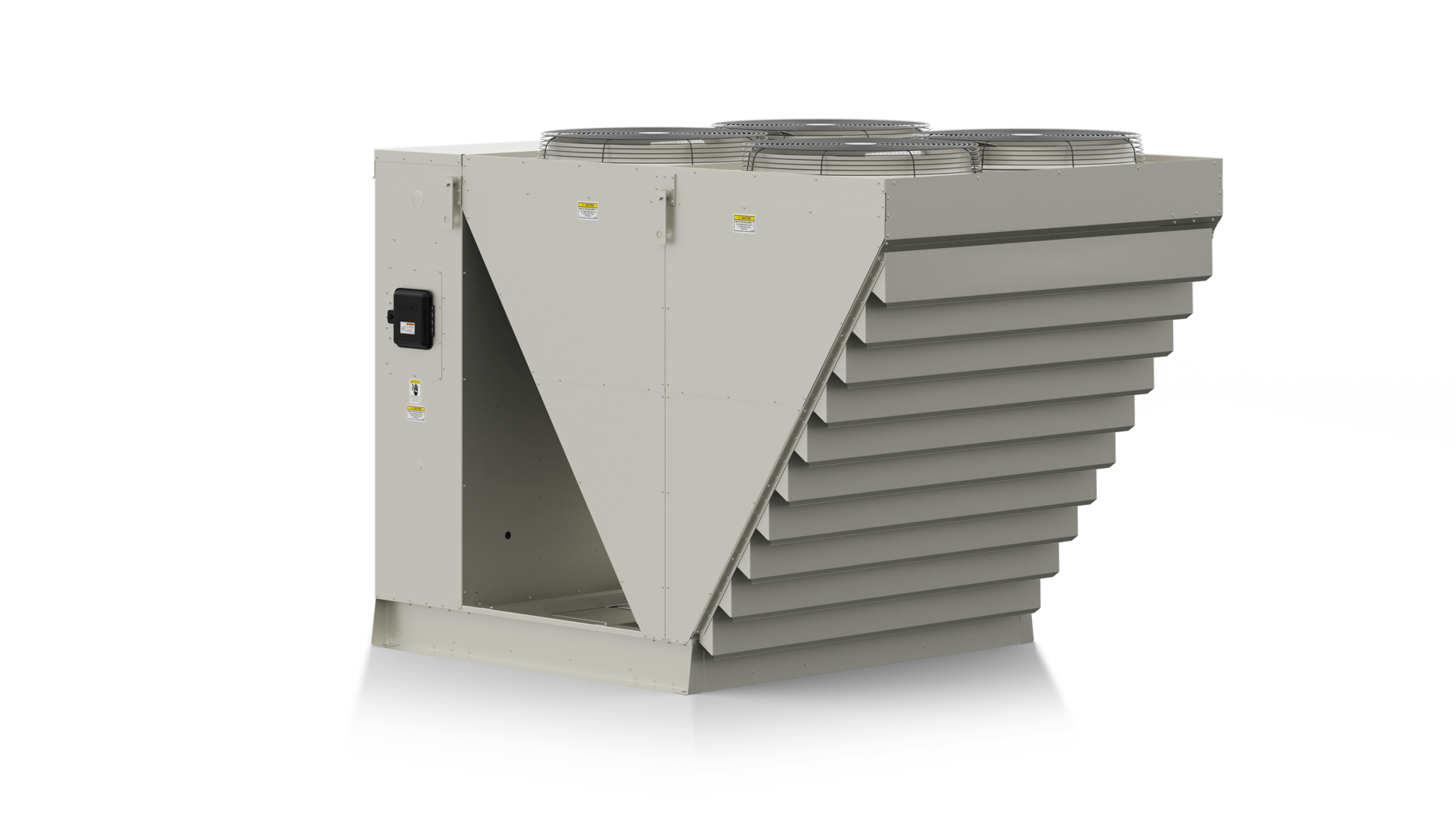

H3 Series

AAON H3 Series horizontal indoor air handling units are designed and engineered for a wide variety of heating, cooling, dehumidification, and ventilation applications. The H3 Series has double wall rigid polyurethane foam injected cabinet construction and variable speed direct drive backward curved plenum fans provide the H3 Series with quiet, energy efficient performance.

450-10,000 cfm

- Documentation

- Performance & Quality

- Features & Options

- Applications

- Knowledge Base

Performance

When matched with AAON condensing units, AAON split systems provide consistent comfort with low energy consumption. Double wall foam insulated construction and direct drive backward curved plenum fans set a high standard of performance.

Quality

- The H3 Series is available in 5 different horizontal sizes, designed with an extremely low horizontal profile for overhead and low clearance installations

- Double wall rigid polyurethane foam injected panel cabinet construction has a higher thermal resistance, or R-value, versus fiberglass construction. Panels include a thermal break, with no metal contact from inside to outside, to prevent heat transfer through the panel and prevent condensation on the outside of the cabinet. Construction also makes the cabinet more rigid and resistance to damage, provides increased sound dampening, and reduces air leakage and infiltration

- Right or left handed piping connections and service access doors to fit the needs of the space

- Double sloped stainless steel drain pans eliminate standing water which can support microbial growth and stainless steel construction resists corrosion that could lead to water leaks and contaminants in the air stream

- Access into fan, filter, and coil sections is quick and easy through service doors with quarter-turn handles

Corrosion resistant exterior/interior paint exceeds a 2,500 hour salt spray test. The paint increases longevity of the unit, especially in harsh environments with salt water or chemical exposure.

Features

- VFD controlled direct drive backward curved plenum supply fans are available to provide precise airflow control and reduced power consumption

- Permanent magnet motor technology with an International Efficiency rating above IE5

- Direct drive backward curved plenum fans are more energy efficient, quieter, and require less maintenance than belt driven and forward curved fans

- Labeled electrical components and color-coded wiring match the unit specific color-coded wiring diagram which is laminated and permanently affixed inside the controls compartment

- Factory provided or customer provided controller can be selected to meet existing or new building control architecture

- Unit controls are contained within a compartment isolated from the air stream with LED service lights for ease of service

- Factory run test report, wiring diagram, and Installation, Operation, and Maintenance manual with startup form are provided in the control compartment of every unit

- Split system modulating humidity control provides energy efficient dehumidification, even with low sensible heat loads, without the temperature swings common with on/off reheat systems

- Multiple high efficiency filtration options, with up to a MERV 14 efficiency rating

Options

- Factory installed total or sensible AAONAIRE energy recovery wheels save heating and cooling dollars by pre-cooling or pre-heating, and dehumidifying or humidifying the ventilation outside air (depending on ambient conditions). Up to 80% of the exhaust air energy can be recovered by the wheel

- Factory installed thermal expansion valve on DX units reduces start up time

- Factory installed mixing boxes for application flexibility. Mixing boxes can include on/off dampers, modulating dampers, or fixed position dampers on the outside and return air streams and can be factory wired to allow for economizer operation

- SCR (Silicon Controlled Rectifier) electric heat control for reduced power consumption, longer heater life, and improved occupant comfort

- Polymer e-coated coils or copper fins with stainless steel casings are available to extend the life of the coils and protect them in corrosive environments

- Corrosion resistant exterior paint is available to protect the cabinet

- Horizontal air handling unit with chilled water or direct expansion (DX) cooling coils from 450 to 10,000 cfm

- Split system heat pump with air-source, water-source, and geothermal configurations allow for energy efficient cooling and heating

- Make up air capability, up to 100% outside air, to meet ventilation requirements

- VAV and single zone VAV capability to minimize system operating costs

- Factory installed high performance hot water, steam, and electric heating

- Natatorium and Pool Room Units; AAONDry units are essential in creating a comfortable indoor pool environment, by precisely controlling temperature and humidity, while minimizing operating costs

Features

- Direct drive backward curved plenum supply fans with rubber isolation mounts are more energy-efficient, quieter, and require less maintenance than belt driven fans

- Factory installed, sensible or enthalpy controlled, AMCA Certified Class 2 low leakage gear driven economizer dampers allow for free cooling

- Labeled electrical components and color-coded wiring match the unit-specific color-coded wiring diagram which is laminated and permanently affixed inside the control compartment

Features

- Direct drive backward curved plenum supply fans with rubber isolation mounts are more energy-efficient, quieter, and require less maintenance than belt driven fans

- Factory installed, sensible or enthalpy controlled, AMCA Certified Class 2 low leakage gear driven economizer dampers allow for free cooling

- Labeled electrical components and color-coded wiring match the unit-specific color-coded wiring diagram which is laminated and permanently affixed inside the control compartment

Features

- Direct drive backward curved plenum supply fans with rubber isolation mounts are more energy-efficient, quieter, and require less maintenance than belt driven fans

- Factory installed, sensible or enthalpy controlled, AMCA Certified Class 2 low leakage gear driven economizer dampers allow for free cooling

- Labeled electrical components and color-coded wiring match the unit-specific color-coded wiring diagram which is laminated and permanently affixed inside the control compartment

Features

- Direct drive backward curved plenum supply fans with rubber isolation mounts are more energy-efficient, quieter, and require less maintenance than belt driven fans

- Factory installed, sensible or enthalpy controlled, AMCA Certified Class 2 low leakage gear driven economizer dampers allow for free cooling

- Labeled electrical components and color-coded wiring match the unit-specific color-coded wiring diagram which is laminated and permanently affixed inside the control compartment

Features

- Direct drive backward curved plenum supply fans with rubber isolation mounts are more energy-efficient, quieter, and require less maintenance than belt driven fans

- Factory installed, sensible or enthalpy controlled, AMCA Certified Class 2 low leakage gear driven economizer dampers allow for free cooling

- Labeled electrical components and color-coded wiring match the unit-specific color-coded wiring diagram which is laminated and permanently affixed inside the control compartment

Features

- Direct drive backward curved plenum supply fans with rubber isolation mounts are more energy-efficient, quieter, and require less maintenance than belt driven fans

- Factory installed, sensible or enthalpy controlled, AMCA Certified Class 2 low leakage gear driven economizer dampers allow for free cooling

- Labeled electrical components and color-coded wiring match the unit-specific color-coded wiring diagram which is laminated and permanently affixed inside the control compartment

Features

- Direct drive backward curved plenum supply fans with rubber isolation mounts are more energy-efficient, quieter, and require less maintenance than belt driven fans

- Factory installed, sensible or enthalpy controlled, AMCA Certified Class 2 low leakage gear driven economizer dampers allow for free cooling

- Labeled electrical components and color-coded wiring match the unit-specific color-coded wiring diagram which is laminated and permanently affixed inside the control compartment