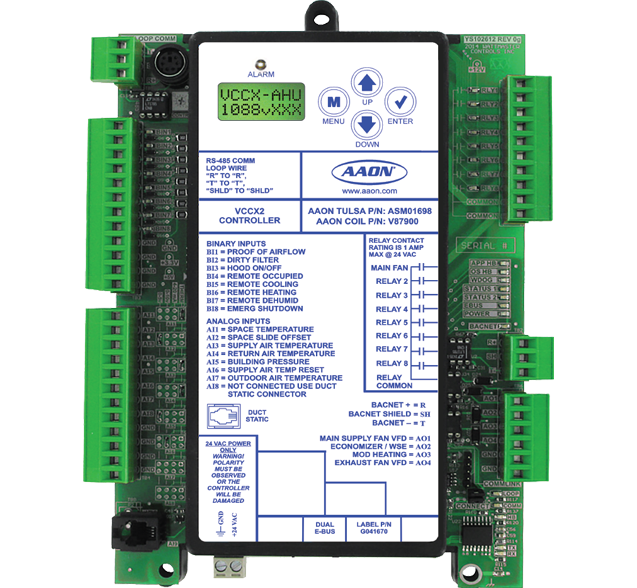

VCCX2 Controller

The VCCX2 Controller is a configurable unit controller that can be used for Constant Air Volume, Variable Air Volume (VAV), Single Zone VAV, Make-Up Air, and Space Temperature Control of a High Percentage Outdoor Air applications. It can be used for air to air heat pump or water source heat pump units.

- VCCX-454 Technical Guide

- VCCX-IP Technical Guide

- VCCX2 Software

- VCCX2 Technical Guide

- Prism 2 VCCX2 Configuration and Setpoints Worksheets

- VCCX2 Controller - Configuration & Setpoints Worksheet (Service Tool) - Interactive

- VCCX2 Controller - Configuration & Setpoints Worksheet (Service Tool) - Handheld

- VCCX2 Component and System Wiring Technical Guide

- VCCX2 Controller and VAV/Zone Controller Operator Interface SD Technical Guide

- VCCX2 Submittal Package

SPECIFICATIONS

-

Features

- Controls up to eight digital compressors

- Controls up to four sets of tandem VFD compressors

- Controls up to 12 stages of heat

- Modulating Cooling Output for Chilled Water Valve Control

- Modulating Heating Output (Hot Water Valve, Steam Valve, SCR Electric Heat Control)

- Full Integration with the AAON Refrigerant System Modules (RSM)

- Full Integration with the AAON MODGAS-X Module

- Full Integration with the AAON MHGRV-X Modulating Hot Gas Reheat Valve Module

- Full Integration with the AAON PREHEAT-X Module

- Advanced Dehumidification Capabilities

- Air to Air Heat Pump and Water Source Heat Pump applications

- Airflow monitoring of Outdoor Air, Supply Air, Return Air, and Exhaust Air Streams with approved EBTRON®, GreenTrolTM, or Paragon Airflow Monitoring Stations

- Airflow control of Outdoor Air Damper

- Single Zone VAV Control w/Optional CAV Heating

- Primary/Secondary Heating Control

- Remote Forced Cooling, Heating, and Dehumidification Control

- Remote Supply Air Temperature Reset Signal

- Adaptive Supply Air Temperature Reset

- Selectable Mode Enable Sensor

- Fan Proving Interlock

- Dirty Filter Alarm

- Emergency Shutdown Input (Smoke Detector/Firestat or other Shutdown Conditions)

- Drybulb/Wetbulb/Dewpoint control of Economizer Operation

- Waterside Economizer Capability

- Building Pressure Control (Direct or Reverse Acting)

- Exhaust Duct Static Control of Exhaust Fan

- Remote Forced Occupied Capability

- Configurable for AAON Return Air Bypass Applications

- IAQ Economizer Reset

- Title 24 Economizer Certified

- Seven-Day, Two-Event-per-Day Scheduling

- 14 Holiday Event Scheduling

- Daylight Saving Time Adjustment

- Trend Logging Capability

- Static Pressure Control for Filter Loading Applications

- Heat Wheel - On/Off Control

- Head Pressure Control

- On-board BACnet® port for connection to an MS/TP network

-

Options

The VCCX2 Controller typically uses Refrigerant System Module(s) to control everything related to the refrigeration circuit(s), including compressors, condensers, and electronic expansion valves while also monitoring for applicable safeties and alarms.

- Different Refrigerant System Modules depending on whether the unit has Digital Compressors or VFD Compressors

- Two E-BUS Expansion ports on the VCCX2 Controller which allow for the connection of the expansion modules described above as well as communicating sensors via modular E-BUS cables.

- Seven communicating sensors available -- two sensors with LCD displays (E-BUS Digital Space Temperature Only Sensor and E-BUS Digital Space Temperature and Humidity Sensor), E-BUS Digital Space Temperature and Humidity Sensor with no display, E-BUS Space CO2 Sensor, E-BUS duct CO2 sensor, E-BUS vertical mounted Outdoor Temperature and Humidity Sensor, and E-BUS horizontal mounted Outdoor Temperature and Humidity Sensor

- Controls up to eight digital compressors

- Controls up to four sets of tandem VFD compressors

- Controls up to 12 stages of heat

- Modulating Cooling Output for Chilled Water Valve Control

- Modulating Heating Output (Hot Water Valve, Steam Valve, SCR Electric Heat Control)

- Full Integration with the AAON Refrigerant System Modules (RSM)

- Full Integration with the AAON MODGAS-X Module

- Full Integration with the AAON MHGRV-X Modulating Hot Gas Reheat Valve Module

- Full Integration with the AAON PREHEAT-X Module

- Advanced Dehumidification Capabilities

- Air to Air Heat Pump and Water Source Heat Pump applications

- Airflow monitoring of Outdoor Air, Supply Air, Return Air, and Exhaust Air Streams with approved EBTRON®, GreenTrolTM, or Paragon Airflow Monitoring Stations

- Airflow control of Outdoor Air Damper

- Single Zone VAV Control w/Optional CAV Heating

- Primary/Secondary Heating Control

- Remote Forced Cooling, Heating, and Dehumidification Control

- Remote Supply Air Temperature Reset Signal

- Adaptive Supply Air Temperature Reset

- Selectable Mode Enable Sensor

- Fan Proving Interlock

- Dirty Filter Alarm

- Emergency Shutdown Input (Smoke Detector/Firestat or other Shutdown Conditions)

- Drybulb/Wetbulb/Dewpoint control of Economizer Operation

- Waterside Economizer Capability

- Building Pressure Control (Direct or Reverse Acting)

- Exhaust Duct Static Control of Exhaust Fan

- Remote Forced Occupied Capability

- Configurable for AAON Return Air Bypass Applications

- IAQ Economizer Reset

- Title 24 Economizer Certified

- Seven-Day, Two-Event-per-Day Scheduling

- 14 Holiday Event Scheduling

- Daylight Saving Time Adjustment

- Trend Logging Capability

- Static Pressure Control for Filter Loading Applications

- Heat Wheel - On/Off Control

- Head Pressure Control

- On-board BACnet® port for connection to an MS/TP network

The VCCX2 Controller typically uses Refrigerant System Module(s) to control everything related to the refrigeration circuit(s), including compressors, condensers, and electronic expansion valves while also monitoring for applicable safeties and alarms.

- Different Refrigerant System Modules depending on whether the unit has Digital Compressors or VFD Compressors

- Two E-BUS Expansion ports on the VCCX2 Controller which allow for the connection of the expansion modules described above as well as communicating sensors via modular E-BUS cables.

- Seven communicating sensors available -- two sensors with LCD displays (E-BUS Digital Space Temperature Only Sensor and E-BUS Digital Space Temperature and Humidity Sensor), E-BUS Digital Space Temperature and Humidity Sensor with no display, E-BUS Space CO2 Sensor, E-BUS duct CO2 sensor, E-BUS vertical mounted Outdoor Temperature and Humidity Sensor, and E-BUS horizontal mounted Outdoor Temperature and Humidity Sensor