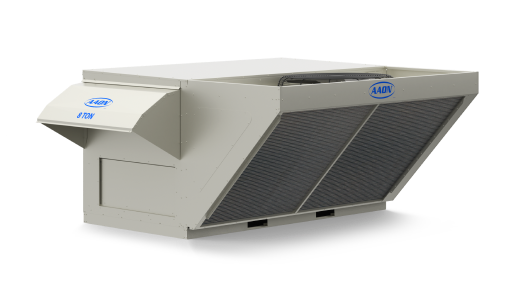

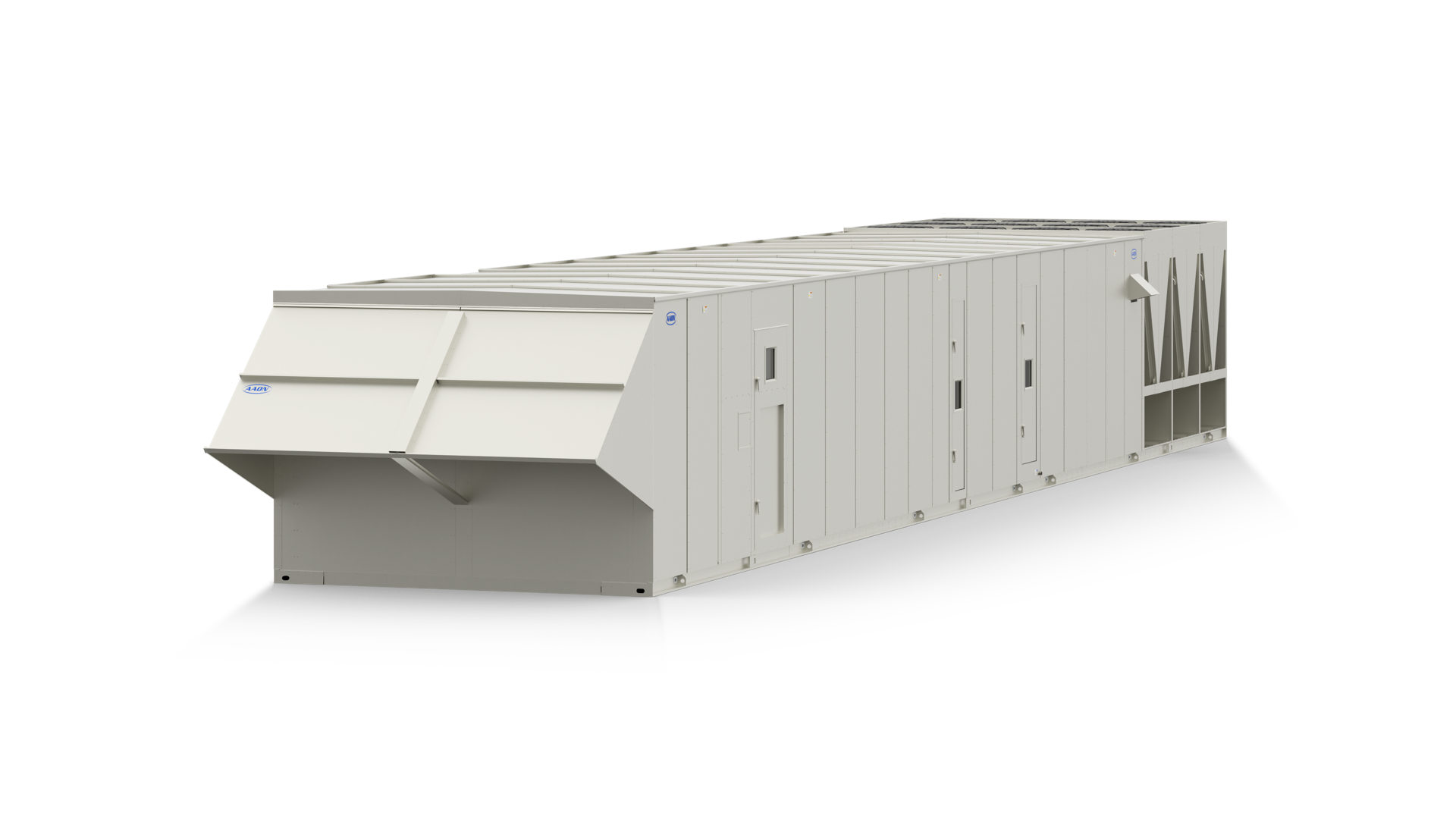

LF Series

The AAON LF Series chillers are designed for premium performance and superior serviceability. The chiller can be provided with factory engineered and installed pumping packages, eliminating the need for a mechanical room.

For improved part load efficiency and consistent leaving water temperature, LF Series chillers are available with variable capacity scroll compressors. Each LF Series chiller is factory tested to ensure proper operation once installed.

SPECIFICATIONS

-

Applications

- Air-cooled condenser chillers with capacities from 4-55 tons

- Compact chiller footprints are ideal for building retrofits, equipment expansion, system redundancy or temporary chilled water applications

- Staged or 10-100%variable capacity R-410A scroll compressors are available to improve part load efficiency and provide load matching cooling

- Multiple factory engineered and installed pumping packages are available, eliminating interior mechanical room building space

- Chillers designed with microchannel condenser coils that increase the effective surface area for heat transfer, leading to a more efficient chiller

-

Performance

LF Series chillers are designed with microchannel condenser coils that increase the effective surface area for heat transfer, leading to a more efficient chiller. Microchannel condenser coils are also up to 30% lighter and use less refrigerant than traditional fin and tube condenser coils.

-

Quality

- The LF Series chiller is factory assembled; before leaving the factory, all water, refrigerant and electrical components are run tested for a quick and easy field startup

- The LF Series is constructed with two inch double wall rigid polyurethane foam panels, making the cabinet more rigid and resistant to damage, while reducing radiated compressor and pump sounds

- Designed for outdoor environments, the LF Series includes a corrosion resistant paint that exceeds a 2,500-hour salt-spray test

- For protection in corrosive environments and a longer coil life, Polymer e-coated condenser coils are available

- Lifting lugs and rigid base pan design with forklift slots for easy job site handling

- Scroll compressors include rubber isolation mounts that minimize vibration

- Access doors with full length stainless steel hinges and lockable handles provide reliability and make the unit easily serviceable

-

Standard Features

- Constant or variable primary pumps can be factory installed in the LF Series chiller. This saves valuable interior building space by eliminating pumps in the indoor mechanical room

- Pumping packages that include a pump, butterfly valves, strainers, and ball valves are available

- Grooved end piping and fittings are provided in all LF Series chillers

- AAON controller compatible with BACnet® protocols

- Unit wiring is completely factory installed with specific color-coded wiring diagrams. Diagrams are laminated and permanently affixed inside control compartment access door

- Control components are labeled to simplify service and scheduled maintenance

- Factory run test report, wiring diagram and Installation, Operation, and Maintenance manual with startup form are provided in the control compartment of every unit

-

Options

- Variable capacity scroll compressors that modulate capacity. This allows the system to maintain consistent leaving water temperatures at all operating conditions. During part load operation, reducing compressor capacity increases part load efficiency and saves valuable system operating costs

- Evaporator options include factory installed and insulated shell and tube heat exchangers or factory installed and insulated brazed plate heat exchangers

- VFD (Variable Frequency Drive) controlled or ECM (Electronically Commutated Motor) driven condenser fans create a wider ambient temperature operating range, increase part load efficiency, and minimize radiated fan sound

- Auxiliary electric heating can be provided in the service vestibule

- Glycol chillers are available for refrigeration and low ambient applications

-

Sustainability

- Corrosion resistant paint exceeds a 2,500 hour salt-spray test

- Optional five year non-prorated compressor warranty

-

Health/IAQ

LF Series chillers are designed with microchannel condenser coils that increase the effective surface area for heat transfer, leading to a more efficient chiller. Microchannel condenser coils are also up to 30% lighter and use less refrigerant than traditional fin and tube condenser coils.

- Air-cooled condenser chillers with capacities from 4-55 tons

- Compact chiller footprints are ideal for building retrofits, equipment expansion, system redundancy or temporary chilled water applications

- Staged or 10-100%variable capacity R-410A scroll compressors are available to improve part load efficiency and provide load matching cooling

- Multiple factory engineered and installed pumping packages are available, eliminating interior mechanical room building space

- Chillers designed with microchannel condenser coils that increase the effective surface area for heat transfer, leading to a more efficient chiller

LF Series chillers are designed with microchannel condenser coils that increase the effective surface area for heat transfer, leading to a more efficient chiller. Microchannel condenser coils are also up to 30% lighter and use less refrigerant than traditional fin and tube condenser coils.

- The LF Series chiller is factory assembled; before leaving the factory, all water, refrigerant and electrical components are run tested for a quick and easy field startup

- The LF Series is constructed with two inch double wall rigid polyurethane foam panels, making the cabinet more rigid and resistant to damage, while reducing radiated compressor and pump sounds

- Designed for outdoor environments, the LF Series includes a corrosion resistant paint that exceeds a 2,500-hour salt-spray test

- For protection in corrosive environments and a longer coil life, Polymer e-coated condenser coils are available

- Lifting lugs and rigid base pan design with forklift slots for easy job site handling

- Scroll compressors include rubber isolation mounts that minimize vibration

- Access doors with full length stainless steel hinges and lockable handles provide reliability and make the unit easily serviceable

- Constant or variable primary pumps can be factory installed in the LF Series chiller. This saves valuable interior building space by eliminating pumps in the indoor mechanical room

- Pumping packages that include a pump, butterfly valves, strainers, and ball valves are available

- Grooved end piping and fittings are provided in all LF Series chillers

- AAON controller compatible with BACnet® protocols

- Unit wiring is completely factory installed with specific color-coded wiring diagrams. Diagrams are laminated and permanently affixed inside control compartment access door

- Control components are labeled to simplify service and scheduled maintenance

- Factory run test report, wiring diagram and Installation, Operation, and Maintenance manual with startup form are provided in the control compartment of every unit

- Variable capacity scroll compressors that modulate capacity. This allows the system to maintain consistent leaving water temperatures at all operating conditions. During part load operation, reducing compressor capacity increases part load efficiency and saves valuable system operating costs

- Evaporator options include factory installed and insulated shell and tube heat exchangers or factory installed and insulated brazed plate heat exchangers

- VFD (Variable Frequency Drive) controlled or ECM (Electronically Commutated Motor) driven condenser fans create a wider ambient temperature operating range, increase part load efficiency, and minimize radiated fan sound

- Auxiliary electric heating can be provided in the service vestibule

- Glycol chillers are available for refrigeration and low ambient applications

- Corrosion resistant paint exceeds a 2,500 hour salt-spray test

- Optional five year non-prorated compressor warranty

LF Series chillers are designed with microchannel condenser coils that increase the effective surface area for heat transfer, leading to a more efficient chiller. Microchannel condenser coils are also up to 30% lighter and use less refrigerant than traditional fin and tube condenser coils.