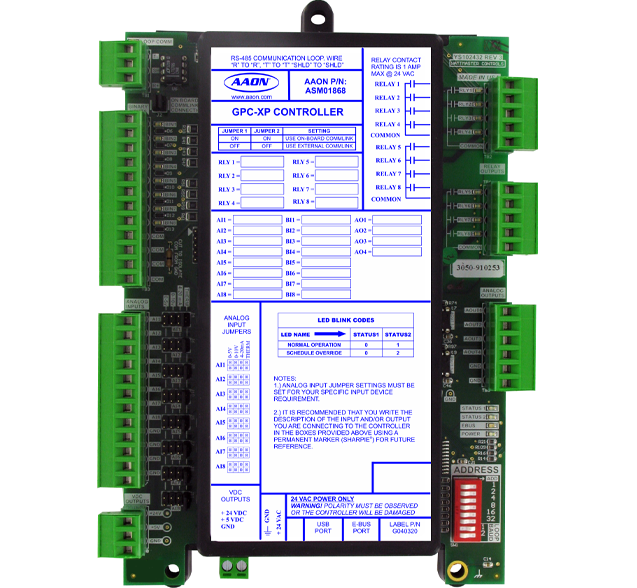

General Purpose Controller

The AAON General Purpose Controller (GPC-XP) provides the flexibility to control unique equipment and processes beyond the standard air-handling unit.

SPECIFICATIONS

-

Applications

The GPC-XP Controller provides user-defined inputs and outputs to fulfill a variety of application needs.

- Exhaust Fan

- In-Floor Zone Heating

- Humidification Control

- Lighting Control

- Fan coil unit

- Chiller Plant

- Boiler Plant

- Heat Pump GEO Thermal Loop Control

- Lead/Lag Control

- Averaging of up to seven analog sensors like CO2 to broadcast to acceptable VCCX2 inputs

- Master Scheduler for site (up to eight unique schedules per GPC-XP)

-

Features

The GPC-XP Controller provides a variety of standard and unique features.

- Configurable analog inputs

- Wet contact binary inputs configured for normally closed or open operation

- Relay outputs for on/off control

- Analog outputs for proportional control signals

- Schedules can be broadcast to other equipment

- On-board Commlink for stand-alone programming

- Configurable with drop down selection

-

Quality

Controls quality and reliability are crucial to a positive ownership experience. AAON unit controllers’ low failure rate is directly attributed to our quality process:

- UL certified to ensure industry safety criteria are met.

- During the design stage, durability is assessed through our environmental and electrical testing.

- Controllers go through continued testing in all phases of production to ensure integrity of the product.

- To complement our quality process, our support teams provide feedback integral for continual improvement.

The GPC-XP Controller provides user-defined inputs and outputs to fulfill a variety of application needs.

- Exhaust Fan

- In-Floor Zone Heating

- Humidification Control

- Lighting Control

- Fan coil unit

- Chiller Plant

- Boiler Plant

- Heat Pump GEO Thermal Loop Control

- Lead/Lag Control

- Averaging of up to seven analog sensors like CO2 to broadcast to acceptable VCCX2 inputs

- Master Scheduler for site (up to eight unique schedules per GPC-XP)

The GPC-XP Controller provides a variety of standard and unique features.

- Configurable analog inputs

- Wet contact binary inputs configured for normally closed or open operation

- Relay outputs for on/off control

- Analog outputs for proportional control signals

- Schedules can be broadcast to other equipment

- On-board Commlink for stand-alone programming

- Configurable with drop down selection

Controls quality and reliability are crucial to a positive ownership experience. AAON unit controllers’ low failure rate is directly attributed to our quality process:

- UL certified to ensure industry safety criteria are met.

- During the design stage, durability is assessed through our environmental and electrical testing.

- Controllers go through continued testing in all phases of production to ensure integrity of the product.

- To complement our quality process, our support teams provide feedback integral for continual improvement.