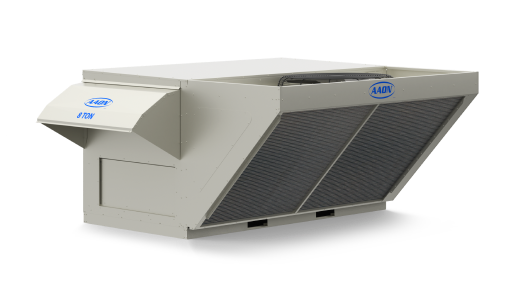

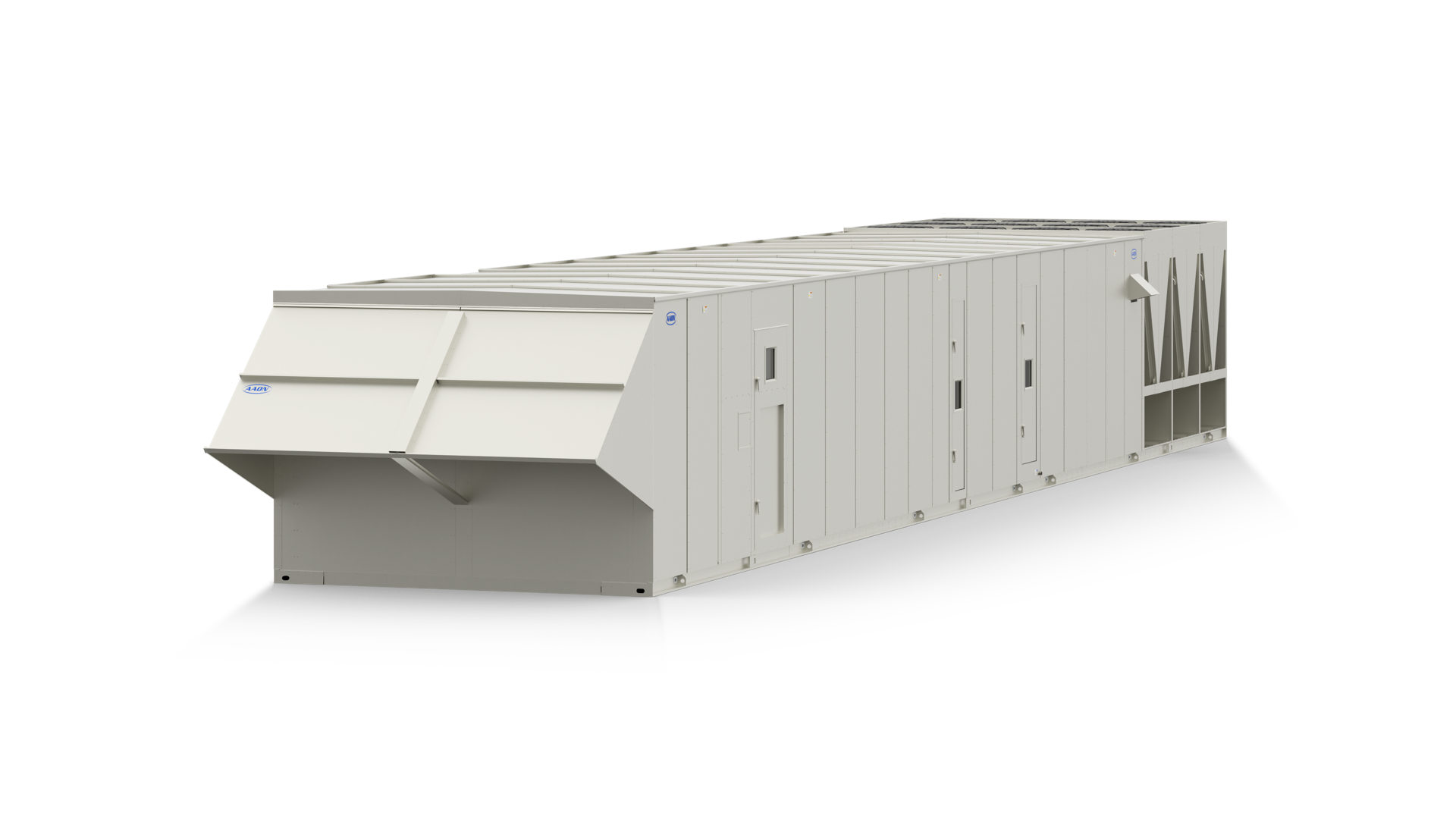

Split Systems

H3/V3/M2 and CF Series

AAON Alpha Split Systems boast the same benefits that customers have come to expect from other AAON products: serviceability, quiet operation, reliability, premium efficiency, world-class construction, and a number of premier options that provide the flexibility to suit any application.

AAON Alpha Split Systems designed to reflect the proven reliability and engineering excellence that can only come from the premier manufacturer of heating and cooling products.

SPECIFICATIONS

-

Applications

- AAON CF Series paired with a H3 Series, V3 Series or M2 Series air handling unit for a complete heat pump split system, ensuring easy installation with factory supplied split system refrigerant line piping and wiring diagrams

- Staged, two-step, or 10-100% variable capacity scroll compressors are available for load-matching cooling and heat pump heating

-

Performance

CF Series air-source heat pump configuration is designed for energy-efficient heating, forming a complete dual-fuel split system of premium performance when paired with AAON air handling units.

-

Quality

- Compressors are factory-installed with rubber isolation mounts on structural decks in a service compartment, where controls are also housed for easy serviceability and quiet operation

- Corrosion resistant exterior paint that exceeds a 2,500-hour salt spray test

- Each refrigeration circuit includes automatic low pressure and manual reset high pressure safety cutouts, and suction and liquid line Schrader valves

- Condensing unit access doors with full-length stainless steel piano hinges and lockable handles provide superior access and serviceability for the isolated compressor and controls compartment

- Access into fan, filter, and coil sections is quick and easy through service doors

-

Standard Features

- Direct drive backward curved plenum fans are more energy-efficient, requiring less maintenance than belt-driven fans, and have a wider operating range than forward curved fans

- ECM (Electronically Commutated Motor) driven or VFD (Variable Frequency Drive) controlled condenser fans for head pressure control and energy efficient capacity modulation

- Condensing units include fully labeled factory installed shutoff valves on each copper connection point

- Factory run test report, color-coded wiring diagram, and Installation, Operation, and Maintenance manual with startup form are included in the controls compartment

- Compressors and controls are housed in a service compartment for easy maintenance

- Variable capacity compressors are available on the lead circuit or all circuits to match the application requirements

- Controls that seamlessly integrate between indoor air handlers and outdoor units, ensuring optimal performance by efficiently managing all functions, including the essential defrosting of the outdoor coil during heat pump operation, safeguarding your equipment, and enhancing overall reliability

-

Options

- Polymer e-coated condenser coils are available to extend the life of the coils and protect them in corrosive environments

- High density foam compressor sound suppression blanket reduces radiated compressor sound

-

Sustainability

- Sustainable design backed by optional five year compressor warranty

- Corrosion resistant exterior/interior paint exceeds a 2,500 hour salt spray test. The paint increases longevity of the unit, especially in harsh environments with salt water or chemical exposure

-

Health/IAQ

- Modulating hot gas reheat provides energy efficient dehumidification, even with low sensible heat loads, without the temperature swings common with on/off reheat systems

- Multiple high efficiency filtration options, with up to a MERV 14 efficiency rating

- AAON CF Series paired with a H3 Series, V3 Series or M2 Series air handling unit for a complete heat pump split system, ensuring easy installation with factory supplied split system refrigerant line piping and wiring diagrams

- Staged, two-step, or 10-100% variable capacity scroll compressors are available for load-matching cooling and heat pump heating

CF Series air-source heat pump configuration is designed for energy-efficient heating, forming a complete dual-fuel split system of premium performance when paired with AAON air handling units.

- Compressors are factory-installed with rubber isolation mounts on structural decks in a service compartment, where controls are also housed for easy serviceability and quiet operation

- Corrosion resistant exterior paint that exceeds a 2,500-hour salt spray test

- Each refrigeration circuit includes automatic low pressure and manual reset high pressure safety cutouts, and suction and liquid line Schrader valves

- Condensing unit access doors with full-length stainless steel piano hinges and lockable handles provide superior access and serviceability for the isolated compressor and controls compartment

- Access into fan, filter, and coil sections is quick and easy through service doors

- Direct drive backward curved plenum fans are more energy-efficient, requiring less maintenance than belt-driven fans, and have a wider operating range than forward curved fans

- ECM (Electronically Commutated Motor) driven or VFD (Variable Frequency Drive) controlled condenser fans for head pressure control and energy efficient capacity modulation

- Condensing units include fully labeled factory installed shutoff valves on each copper connection point

- Factory run test report, color-coded wiring diagram, and Installation, Operation, and Maintenance manual with startup form are included in the controls compartment

- Compressors and controls are housed in a service compartment for easy maintenance

- Variable capacity compressors are available on the lead circuit or all circuits to match the application requirements

- Controls that seamlessly integrate between indoor air handlers and outdoor units, ensuring optimal performance by efficiently managing all functions, including the essential defrosting of the outdoor coil during heat pump operation, safeguarding your equipment, and enhancing overall reliability

- Polymer e-coated condenser coils are available to extend the life of the coils and protect them in corrosive environments

- High density foam compressor sound suppression blanket reduces radiated compressor sound

- Sustainable design backed by optional five year compressor warranty

- Corrosion resistant exterior/interior paint exceeds a 2,500 hour salt spray test. The paint increases longevity of the unit, especially in harsh environments with salt water or chemical exposure

- Modulating hot gas reheat provides energy efficient dehumidification, even with low sensible heat loads, without the temperature swings common with on/off reheat systems

- Multiple high efficiency filtration options, with up to a MERV 14 efficiency rating