Commercial Cooling Systems – Solutions for Every Application

There are many different commercial HVAC systems that are capable of providing cooling to buildings.

These systems differ from residential HVAC systems in that they are focused on large cooling applications for areas such as office buildings, event centers, and schools. Each system possesses distinct characteristics that make it preferred for specific commercial applications. The key to selecting the right cooling systems is understanding the priorities and attributes of the building and matching these to the features of a cooling system.

Introduction to Commercial Cooling Systems

Most buildings require some degree of cooling due to the heat and moisture generated by people and equipment inside the building and the heat transferred through the building envelope when it is hot outdoors. Cooling systems are designed to maintain defined space conditions. In commercial buildings, the acceptable range for temperature and humidity is often determined based on comfort. Many commercial buildings house people performing tasks – schools, offices, healthcare, and sporting venues. The correlation between productivity and comfort makes investing in cooling a wise choice for these building owners. Other commercial buildings are evaluated based on occupant satisfaction, such as hotels, restaurants, theaters, retail, and airports, again making cooling an important investment. There are, of course, some commercial buildings where occupant comfort is not the priority, but instead the equipment or product housed within the space is of greater importance, like museums and laboratories. Cooling is critical whether for productivity, satisfaction, function, or a combination of these, although the desired set points may differ based on the application.

Cooling is not reserved for commercial buildings. It is commonly found also in residential (single-family, apartments, townhouses, condominiums) and industrial buildings (manufacturing, power plants, data centers, warehouses, distribution centers). Much of the same cooling technology is used in residential, commercial, and industrial buildings, but the systems used differ in their capacity, complexity, and control to meet the application's needs. This article will focus on cooling systems commonly applied to commercial buildings.

Need assistance?

Your local AAON rep is ready to help.

👉 Find a Rep

A cooling system removes heat from the interior of a building to maintain the desired space conditions. This heat is most commonly rejected outdoors, although it can be used in heat recovery systems, such as domestic water heating. With very few exceptions (absorption chillers and evaporative coolers), all cooling systems require the use of the refrigeration cycle. The refrigeration cycle routes refrigerant through piping from the compressor to two heat exchangers, one absorbing heat and the other rejecting heat, separated by an expansion device. Refrigerant is necessary because its properties produce temperatures low enough to meet the cooling demand. The type of commercial HVAC equipment dictates how the cooling system connects the conditioned space and the outdoors for heat rejection and where the refrigerant resides in the system.

Variable Speed Scroll Compressor

Types of Commercial Cooling Systems

Commercial cooling systems can be classified based on whether heat transfer occurs through radiation (radiant cooling) or air circulation (natural convection or forced air using a fan). In the U.S., due to their many limitations, radiant cooling and natural convection are not as prevalent as forced air in cooling systems. This article focuses on the more popular forced air cooling systems used in commercial buildings.

In a forced air cooling system, a fan moves warm air from the space over a cold heat exchanger (the cooling coil). As the air passes over the cold coil, heat is absorbed by the medium in the coil, cooling the air down. The cool air is delivered back to the space, maintaining the desired space conditions. The medium in the coil, having absorbed the heat, is now warm. The manner in which the heat leaves the building differs depending on the cooling system used. Forced air cooling systems are further categorized as either Direct Expansion (DX) or hydronic, based on whether the medium in the coil is refrigerant or water.

Direct Expansion (DX)

A forced air commercial cooling system that places a DX coil in the space air stream allows for the most compact cooling configuration with the fewest components. This makes the system simpler to control, operate, and maintain. DX systems are frequently used for these reasons, especially for small applications. There are two types of DX systems – packaged and split.

As the name implies, packaged systems have all the necessary parts located in a single housing – the fan, air filters, and refrigeration cycle components. These units are located outdoors to allow heat rejection from the second heat exchanger (the condenser coil), and a condenser fan is incorporated to promote this heat rejection process. Usually, these units are placed adjacent to the served space so that ductwork can be easily routed between the unit and the space or eliminated altogether. Types of packaged DX cooling systems include: packaged rooftop units (RTU), packaged air-source heat pumps (ASHP), packaged terminal air conditioners (PTAC), and window units.

When DX cooling is desirable but the space being served is not near the exterior of the building, a split system is used. In a split system, the refrigeration cycle components are split between two units. One indoor unit houses the space air circulation fan, the evaporator coil, and the expansion device. This unit is connected via refrigerant piping to the exterior unit that contains the condensing coil, the compressor, and the condenser fan. The cooling process is the same as the packaged unit. Types of split system DX cooling include: air handling units (AHU), fan coil units (FCU), furnaces with an air conditioning coil, and mini-splits. Each of the indoor units is connected by refrigerant piping to a dedicated remote air-cooled condensing unit located outdoors. A heat pump also falls under this classification, but is different from the other units in that it contains a reversing valve. This valve enables the refrigerant to change direction, and the coils that absorb and reject heat to change function, therefore providing heating or cooling based on space demand. Another system that falls within the split system category that provides both heating and cooling is the variable refrigerant flow (VRF) system. Rather than having a single outdoor unit dedicated to each cooling coil, VRF systems connect refrigerant piping between multiple unit coils to a single exterior unit. Heat pump and VRF systems are becoming a more common commercial HVAC solution because of their inherent capability of providing both heating and cooling without needing to add additional equipment.

Hydronic

Commercial HVAC systems that depend on water as part of the process are called hydronic systems. Water-cooled systems are favorable for larger cooling applications, especially when the desire is to connect multiple pieces of equipment to a single cooling source to improve efficiency. Nearly all hydronic systems are split systems since they require a second piece of equipment containing the refrigeration cycle to achieve the desired water temperatures. In a traditional hydronic split system, chilled water is routed through the cooling coil in the unit. Space air is cooled as it passes over this cooling coil, and the chilled water in the coil absorbs this heat. The warm chilled water (CHWR) needs to be cooled, requiring a chiller. A chiller uses the refrigeration cycle, but instead of the evaporator removing heat from the space air, it removes heat from the chilled water. A pump is also needed to move the cool chilled water (CHWS) from the chiller to all the system cooling coils and to circulate the warm chilled water (CHWR) back to the chiller. The types of units that contain hydronic cooling coils include air handling units (AHU), rooftop units (RTU), and fan coil units (FCU).

The two most common chiller types are air-cooled and water-cooled. Air-cooled chillers are located outdoors and contain all the refrigeration cycle components. Chilled water supply (CHWS) from the chiller is distributed to all the coils within the system through piping. The warm return water (CHWR) is pumped outdoors to the chiller, where the evaporator extracts the heat from the water and the condenser rejects the heat to the atmosphere. The now cooled chilled water (CHWS) begins the cycle again. An alternative is to use a water-cooled chiller, which extends the chiller's life and increases energy efficiency in larger capacity applications. A water-cooled chiller is located indoors; therefore, it requires a cooling tower, another piece of equipment, to reject the heat via a separate water stream to the outdoors.

A water-source heat pump is also technically a hydronic system because water is used for a portion of the heat transfer function. However, they do not work like the other hydronic cooling systems identified above. Water-source or ground-source heat pump units are located inside the building near the space they serve, minimizing the length of ductwork. The heat pump unit houses the fan, air filters, and refrigeration cycle components just like the packaged DX system, but because it is located indoors, an alternate heat rejection path is needed. Water is used as the medium to absorb the heat from the heat pumps. This water loop connecting all the system heat pumps (called the heat pump water loop) is routed to either a cooling tower (water-source) or the ground (ground-source) to reject the heat. To optimize the system's energy efficiency, multiple heat pumps are typically connected to a common water loop. Heat pumps differ from the other hydronic cooling systems discussed because they have a reversing valve that enables the refrigerant cycle to alter function and provide heating from the same coil that was cooling.

Selecting the Right Cooling System for Your Business

There are several cooling systems to choose from. Each system incorporates different features or possesses characteristics that may be more or less important to an application. Some more common items considered when selecting between cooling systems are location, building characteristics, indoor environmental quality (IEQ), and cost.

Location

The physical location of a building affects the cooling system. Indeed, climate plays an important role. The hotter and more humid the outdoor conditions, the larger the cooling system needs to be. This impacts the selection because some cooling systems are limited in capacity, while others are best aligned with large demand situations. Not only does the system selected need to meet the peak cooling demand, but it must also be able to modulate in situations where the load is not constant, which some systems are better at accommodating than others. Climate also limits the equipment's placement, narrowing the cooling system options. When placing commercial HVAC units outdoors, year-round accessibility, clearance requirements, and premature wear must be accounted for, especially in harsh climatic locations presenting obstacles such as deep snow and corrosive salt air.

Beyond climate, the location will dictate the locally adopted codes and ordinances, which can eliminate the potential use of some systems. These regulations can pertain to refrigerant use, placement of equipment, and unit performance.

Building Attributes

The building design and layout contribute to the cooling system selection by dictating where the system components can be placed. When accounting for equipment placement, several questions have to be answered.

-

Are there rooms inside the building to house equipment?

-

How large are the equipment rooms, and where are they relative to the commercial spaces served?

-

Is there space above the ceiling or below the floor for equipment to be placed?

-

What is the roof configuration – flat or sloped?

-

Can the roof support the added weight of cooling equipment?

-

Is exposed equipment on the roof or the exterior of the building acceptable?

The answer to these questions will significantly narrow the potential cooling systems that can be used in a building.

Ready to find the right cooling solution for your project?

Connect with your local AAON representative for expert guidance.

👉 Find a Rep Near You

Indoor Environmental Quality

Since most buildings exist to serve the occupant, it is essential to provide an environment that promotes well-being. The features of a productive environment are encapsulated by the phrase indoor environmental quality (IEQ) – good indoor air quality, comfort, acoustics, and lighting. The cooling system selection can impact the first three of these items.

Good indoor air quality is achieved through the introduction of ventilation and the cleaning of recirculated air. Not all cooling systems can deliver outdoor air, or only do so in small quantities. Therefore, a second unit would need to be used to reach the necessary indoor air quality standards, increasing the cost and complexity of the system. The quality of the air filters used in the cooling unit will contribute to the cleanliness of the circulated air. Not all cooling units are designed to overcome the resistance imposed by high-efficiency air filters.

Cooling is regularly cited as a criterion for comfort. The challenge with thermal comfort is that it is subject to personal preferences and characteristics like clothing and activity level. The more control the occupant has in setting the temperature within their space, the greater their satisfaction. The level of control (individual room control, a controller for a group of rooms, a single temperature set point for a building, etc.) is a characteristic of the cooling system selected. Smaller units inherently serve a small area, whereas larger units typically require more complex controls and zone-level devices to enable smaller control zones.

Acoustics is the last of the IEQ functions impacted by the cooling system. The building occupants’ sensitivity to noise and vibration can affect the selection of the building cooling system. Cooling equipment located in or immediately adjacent to spaces sensitive to higher sound levels can result in undesirable noise generation; therefore, systems that can be positioned more remotely need to be considered.

Cost

Cost plays an important role when comparing the different cooling systems. Exploring if incentives or rebates exist for specific cooling systems can reduce the first cost of qualifying cooling systems, expanding the options. The initial cost of the cooling equipment and its installation are generally factored in, but many other costs over the life of the system should also be considered. The cost of operating the system cannot be overlooked, as these costs will outweigh the initial costs. Understanding the utility energy costs and pricing structure, as well as the cooling system energy consumption, is necessary. This is where the decision-making process accounts for cooling system energy efficiency. In addition to the regularly occurring utility expense, the cost associated with proper commercial HVAC maintenance needs to be considered. Generally, the more equipment within the system, the more complex the system and its controls, which translates to the need for more expertise, time, and effort by staff, increasing the cost to maintain the system. Another factor that can potentially increase the maintenance expense is the equipment accessibility. For example, multiple, distributed, smaller units located above the ceiling take more time to maintain than a single larger unit in a mechanical room. Inadequate or poorly executed maintenance can result in equipment not lasting as long, increasing the overall cost of the system and the risk associated with failure. Failure compromises the function of the building and its occupants, again becoming expenses that should be factored when comparing cooling systems.

As expressed in this section, there are many factors to consider when selecting a building cooling system. Some of these factors are more quantifiable than others. The typical cooling system selection procedure begins with prioritizing the needs of the commercial spaces being cooled, then eliminating the systems that do not meet these needs, followed by conducting a life cycle cost analysis to establish the financial viability of the remaining systems, and then evaluating those items that could not be quantified to determine the best system for the application.

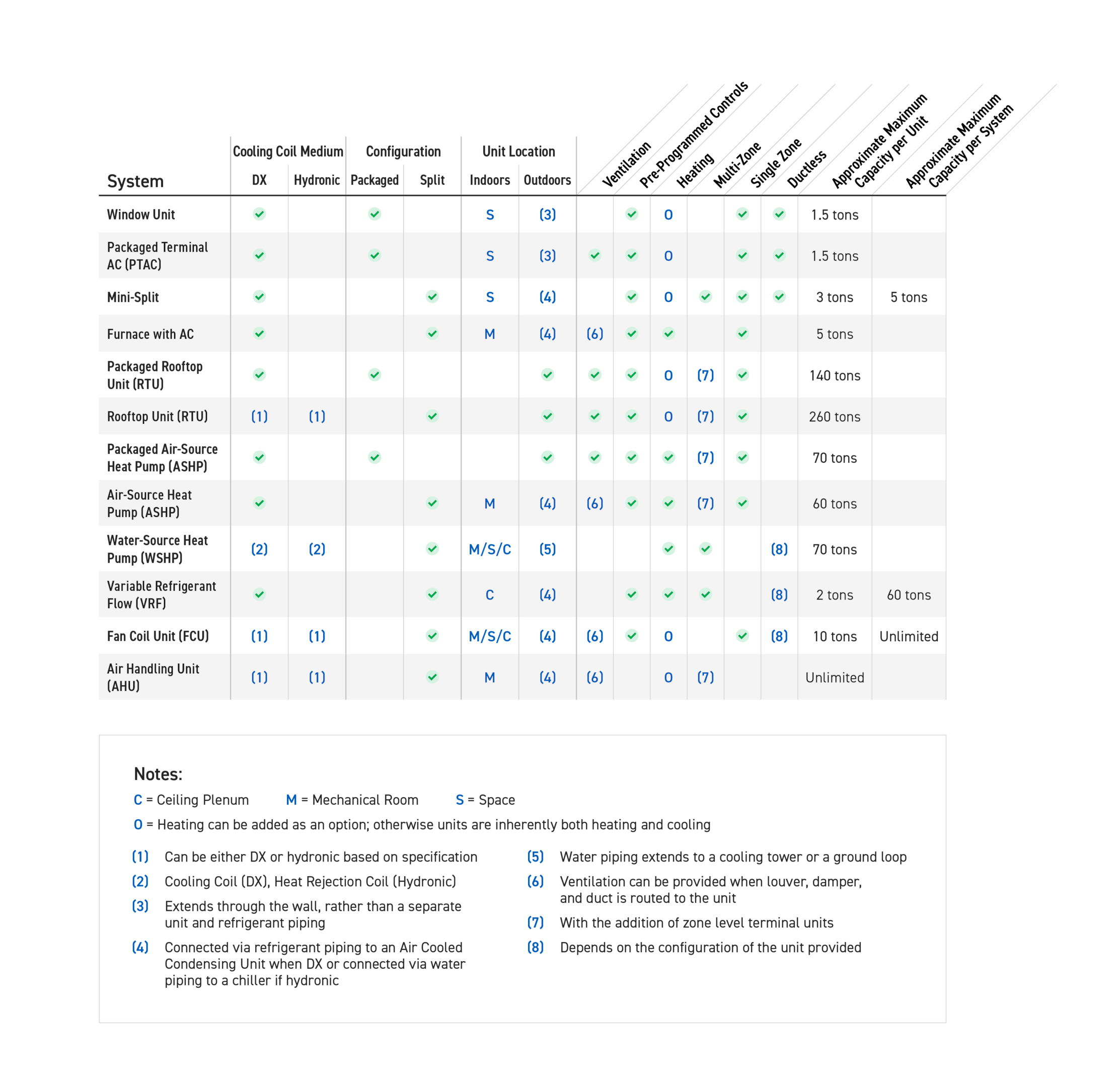

Below is a table to assist when comparing the attributes of the many different cooling systems.

Commercial Cooling System Attributes

AAON’s Commercial Cooling Solutions

AAON manufactures highly configurable commercial HVAC equipment that answers customer-specific needs in any environment. Through the design, manufacturing, and rigorous testing, their cooling equipment exceeds standard efficiency thresholds and provides superior longevity and ease of regular maintenance.

Packaged DX:

AAON RN Series Packaged Rooftop

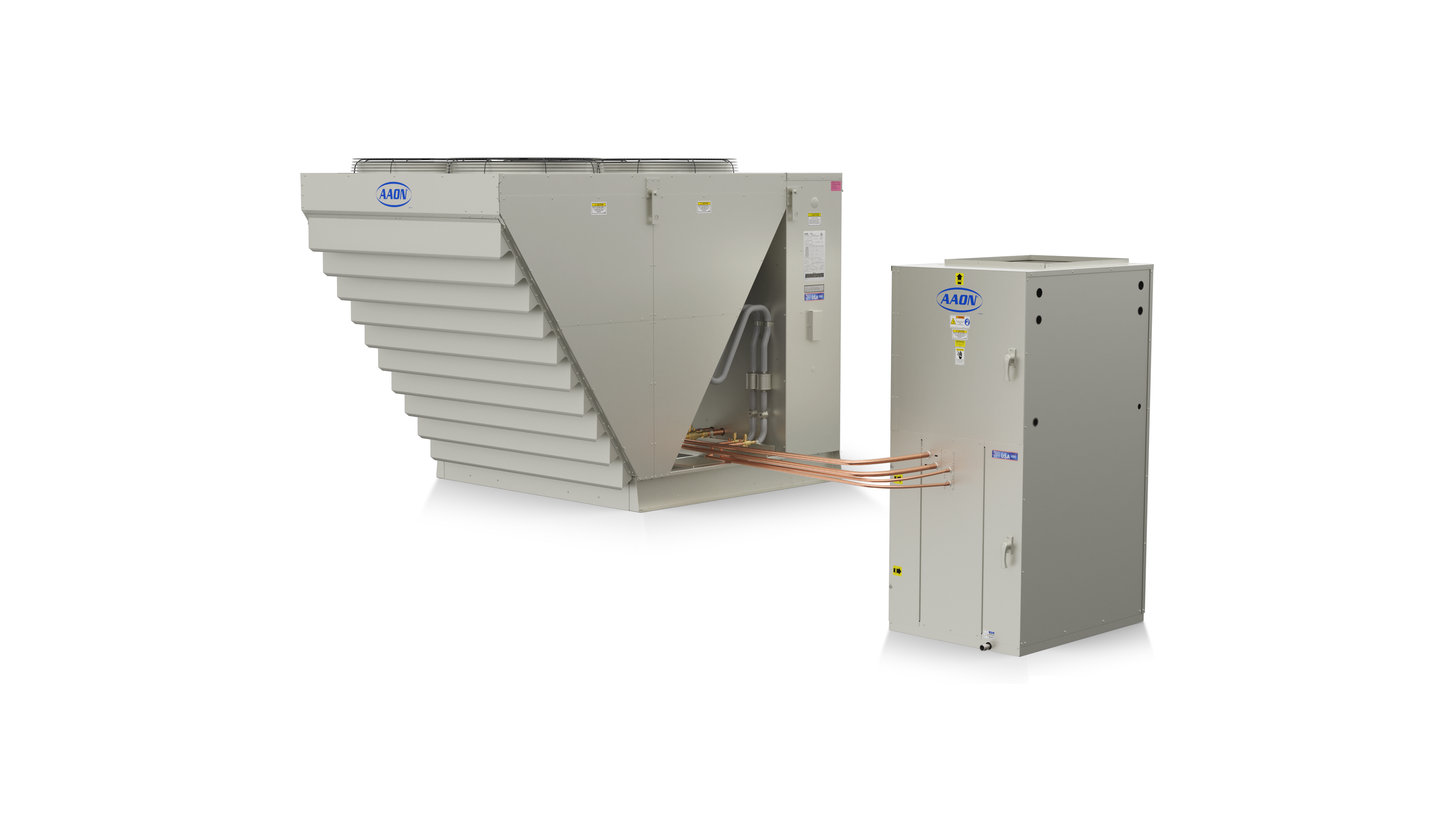

Split System DX:

AAON Split System

Hydronic:

Frequently Asked Questions (FAQs) – Commercial Cooling Systems

-

What is the most common commercial cooling system?

A forced air cooling system is most commonly used commercial applications. Of the systems that fit within this category, the most prominent is the packaged RTU. The popularity of rooftop HVAC units, especially packaged RTUs, can be attributed to their ease of installation, variability in capacity, integral ventilation, and control and maintenance simplicity.

-

What are the primary classifications of commercial cooling systems?

Traditional commercial forced air cooling systems can be classified based on two criteria. The first is whether the unit is packaged or split. In a packaged system, all the components are contained in a single housing located outdoors. A split system, on the other hand, consists of more than one unit. With at least one outdoor unit, the system components are connected by piping. The medium contained in the cooling coil is the second criterion. If the medium is refrigerant, the system is a DX system, whereas if it is water, it is hydronic. Water source heat pumps are a third classification. This unit uses refrigerant within the unit for cooling, but uses water as the means of rejecting heat to the outdoors.

-

What should be considered when selecting the right commercial cooling system for my business?

Several factors should be considered when selecting a commercial cooling system.

· Location – Climate, load, and adopted codes and ordinances

· Building characteristics – Equipment placement

· Indoor environmental quality (IEQ) – Ventilation, filtration, comfort, and noise

· Cost – First cost, operational cost, and risk of failure

Every building application will prioritize these factors differently, ultimately resulting in a need to assess the criteria and the potential cooling systems for their appropriateness in each situation.

-

When a commercial cooling system reaches end-of-life, should it be replaced with the same system?

As with all technology, advancements are being made in cooling systems. Therefore, exploring alternative system options is appropriate when replacing an existing cooling system. In some cases, the same type of cooling system may be used, but the new unit(s) provide better efficiency. As part of the assessment, confirming that the building use, function, or priorities have not changed is imperative. Changes could alter the capacity of the needed system or the preferred system for the application. Many features in new cooling systems can enhance the system's performance, making it in the owner's best interest to consider alternative cooling options at the end of an existing system’s life.

-

Why choose AAON for commercial cooling solutions?

AAON manufactures highly configurable HVAC system solutions that answer customer-specific needs in any commercial environment. Through the design, manufacturing, and rigorous testing of their cooling equipment, they exceed standard efficiency thresholds and provide superior longevity and ease of maintenance.

Looking to learn more? Check out our YouTube channel.