Commercial HVAC Controls – Optimizing Building Efficiency

In an HVAC system, the controls act as the "brain" of the system. They monitor how the unit is performing while also sending signals to initiate the proper sequences. These sequences ensure energy efficiency, cost savings, and longer equipment life.

Introduction to Commercial HVAC Controls

Commercial buildings’ indoor environments are maintained using heating, ventilation, and air conditioning (HVAC) equipment. When selected and installed correctly, this equipment provides comfort even during cold winter and hot summer conditions and when the building varies between empty and fully occupied. Control is key to enabling the HVAC equipment to adjust to these variations. Without controls, the equipment would provide much more heating, cooling, or ventilation than needed under these partial load conditions, resulting in discomfort and wasting tremendous energy. Commercial HVAC equipment often contains automatic controls, eliminating the need for constant manual adjustments to optimize unit performance. In many larger building applications, these unit controls connect to system- or enterprise-level controls to allow communication and monitoring beyond the unit itself.

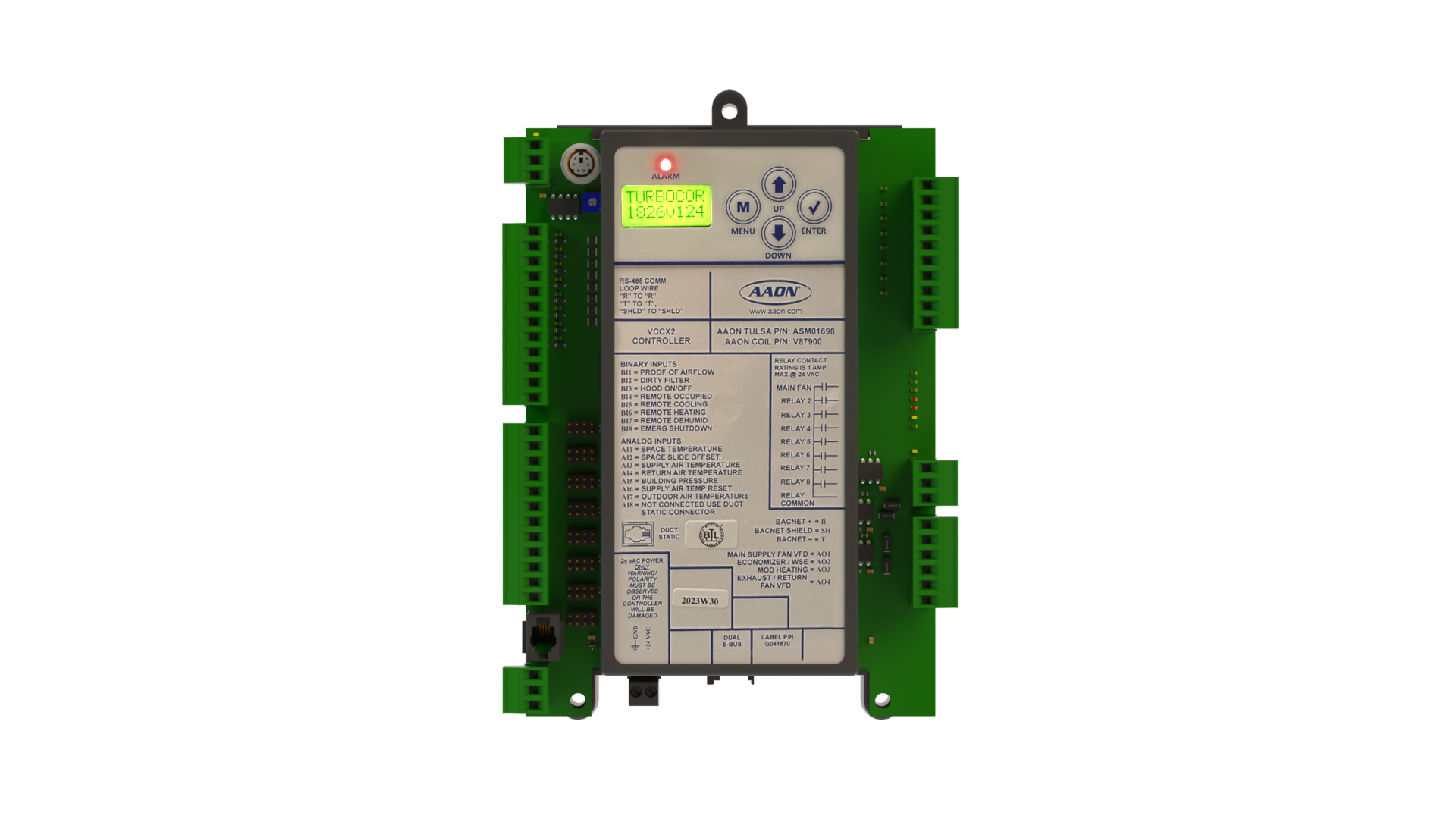

AAON VCCX2 Controller

Looking for guidance or solutions?

Connect with an AAON representative in your area.

👉 Find a Rep

Different Types of Commercial HVAC Controls

The primary control types used in commercial HVAC systems are pneumatic and digital controls.

Pneumatic Controls

Pneumatic controls is a legacy system that consists of an air compressor, compressed air piping, control devices such as actuators on valves or dampers, and sensors such as thermostats, humidistats, or pressure sensors. The air compressor provides air pressure to the piping connecting the control device and the sensor. The sensor monitors the defined setpoint (temperature, humidity, static pressure). When the conditions exceed the defined setpoint value, the sensor releases air from the line. This opens or closes the control device (actuators) using springs and diaphragms that respond to the resultant change in line pressure. Pneumatic systems are durable and time-tested, but their simplicity limits the sophistication of the controls commands and the difficultly of incorporating it into a modern building management system, compromising the potential for energy savings. This, as well as the maintenance and operational expenses associated with the generation and distribution of compressed air, have led to pneumatic controls only being installed in very particular specialty applications. However, they remain in many existing buildings as general controls that have not been upgraded to digital controls.

Direct Digital Controls (DDC)

Digital control, also known as direct digital control (DDC), is the default control method used today in commercial HVAC systems. These systems use microprocessor technology with digital controllers and sensors to collect, process, and respond to data to maintain the desired setpoints. The digital nature of the system enables much more capability than possible with pneumatic controls while eliminating the maintenance, noise, and energy use associated with compressed air. DDC provides the following advantages compared to pneumatics:

- Easier to implement complex control sequences

- Normally more precise and accurate

- Allows for retime monitoring and data logging

- Can be adjusted from remote

- Can be easily integrated with other building systems controls

Commercial DDC controls can be implemented at different levels within a system.

Basic-Level

The most basic level of control is integral to the HVAC equipment. These controllers are designed, configured, and tested to properly operate the unit without additional programming. The benefit of unit-level control is its simplicity, reliability, and low cost. This is ideal for light commercial applications such as small office or retail spaces. Using unit-level controls for a larger building presents a challenge because each unit functions independently preventing centralized supervision and the ability for the units to communicate with each other.

System-Level

System-level controls enable all the HVAC components to be interconnected as a network, which are monitored and adjusted from any location using a Building Automation System (BAS). This allows for more effective use of facility maintenance personnel’s time and resources since they do not have to go to each individual unit to check or adjust its function and unit performance can be remotely tracked, compared, and integrated to respond to the other units.

Enterprise-Level

It is most common for today’s medium and large commercial HVAC systems to employ enterprise-level controls. This expands the Building Automation System (BAS) level of control to incorporate building system control beyond HVAC, such as lighting, security, and life safety. The significant advantage of a Building Automation System (BAS) is its ability to share information between systems to optimize both first cost and operation. A single occupancy sensor, for example, can respond to someone entering a space by notifying security, turning on the lights, adjusting the thermostat from setback conditions to the occupied setpoint, and increasing the amount of ventilation delivered. This saves the cost and effort of purchasing, installing, and maintaining a separate sensing device for each system. On top of this, an operation that is responsive to real-time conditions enhances indoor air quality, improves comfort, saves energy, and reduces utility costs.

Digital controls make integrating new technology possible, further enhancing the potential for system control to positively impact system operation. Since Building Automation System (BAS) is an interconnected network of devices, data-driven optimization and smart buildings employing machine learning and AI are beginning to be implemented. Predictive maintenance, enhanced facility function, and optimized energy management are anticipated to be the future for the HVAC industry.

DDC Control System Components and Function

The key components of a DDC system include inputs, outputs, controllers, and the user interface. Each is described below.

Inputs are sensors and devices that collect information about the environment and/or equipment status, which is sent to the controller. These inputs are classified as either digital or analog.

Digital inputs are simple in that they are binary (two option) signals that report status or position, such as:

- on/off (i.e., motor, fan, pump, or compressor)

- open/close (i.e., valve or damper)

- alarm/no alarm (i.e., fire alarm or building emergency)

- flow/no flow (i.e., water or air)

- above/below a defined value (i.e., outdoor air temperature or static pressure)

Analog inputs, on the other hand, measure a range of values and report the condition. Analog inputs include:

- temperature (i.e., room temperature or coil discharge temperature)

- flow (i.e., quantity of airflow or waterflow)

- pressure (i.e., interior building pressure or duct static pressure)

- humidity (i.e., space humidity or outdoor humidity)

- position (i.e., position of a modulating damper or a valve)

- enthalpy (i.e., return air enthalpy or outdoor air enthalpy)

Outputs provide a signal to control physical devices based on the direction from the controller. Outputs are also classified as either digital or analog.

Digital output signals commonly perform the following functions:

- on/off (i.e., start or stop a motor, fan, pump, or compressor)

- open/close (i.e., open or close a valve or damper)

Analog outputs provide a variable signal that modulates or stages device function. Examples include:

- Valve or damper actuator modulation (i.e., partially open or closed)

- Motor speed (i.e., increase or decrease fan or pump speed)

- Electric heating coil activation (i.e., increase or decrease power for more or less heat)

- Setpoint adjustments (i.e., change setpoints of other controllers)

The controller is a computer that acts as the brain in a DDC system. It collects the data provided by the input sensors, processes the information based on programmed logic and setpoints, and commands the appropriate actions through output signals to control devices. The controller can be pre-programmed, as is the case for most packaged equipment, or custom programmed when using a Building Automation System (BAS). Custom programming increases the complexity of the design because a detailed narrative that communicates the settings for all the sensors under the various operational modes and how the system components are to respond must be written. This narrative is called the sequence of operations (SOO) and is usually written by the design engineer. The controls contractor uses the SOO for programming the system operation. Customized programming adds cost to a project and increases the potential for issues at system start-up, but is necessary for Building Automation System (BAS) containing complex HVAC systems, multiple building systems, or operations that are unique to an application.

Ultimately, HVAC system controls exist to satisfy the building’s occupants. This requires monitoring the system and adjusting as schedules, preferences, or needs change. A graphical user interface allows the staff who manage the facility to have a visual tool and interact with the system easily. This interface can be built into the individual unit as an interactive screen for a packaged piece of equipment or provided at the computer workstation, acting as the controller in the Building Automation System (BAS). The user interface can be extended to web or cloud-based dashboards, mobile apps, or other technology that meet the remote access needs of building owners.

Benefits of HVAC Controls for Commercial Buildings

HVAC controls are critical to proper system function, but also provide cost savings, improve occupant comfort, and are required to comply with code requirements. Although the first cost of a more sophisticated control system may be higher, savings can offset this through decreased energy use, more efficient maintenance, and shared sensors between systems.

Energy - Improper HVAC operation can result in much more energy being used than necessary as experienced when a space is conditioned and provided the same ventilation independent of occupancy. A control system can be programmed to monitor occupancy using sensors and adjust system operation to provide different space conditions and outdoor airflow based on occupancy saving both fan and heating/cooling energy. This is just one example of many where controls save energy.

Maintenance - Facilities staff can use a control system to manage their resources more effectively. The ability to monitor and make changes to the system from a remote location decreases the number of personnel required on-site. It also increases the speed of responsiveness in the case of a problem reducing downtime and, in many cases, also saving energy and stress on other components in the system. Reports generated by the system can also be used for preventive maintenance and to create better-informed and accurate budget predictions, leading to more dependable and better-performing systems.

Comfort - HVAC systems that operate correctly result in greater occupant comfort and satisfaction, contributing to less distraction and greater productivity.

These advantages benefit building owners, but the energy savings and better indoor conditions also benefit greater society; therefore, minimum control requirements are included in the building codes, standards, and certification programs.

Selecting the Right Level of Commercial HVAC Controls

When deciding between the different levels of HVAC controls - unit level controls, controls that are limited to only the HVAC system, or implementing a Building Automation System (BAS) that is customized to control multiple systems - the budget, the function of the building, the type of HVAC system, and the targeted level of optimization must be considered. When focused on keeping the budget low, selecting pre-programmed controls provides the most significant value. Depending on the HVAC units selected, connecting multiple pre-programmed units may be possible. This has the benefits of centralized controls without the cost of a custom-programmed Building Automation System (BAS). There are also opportunities for integrating controls for very basic external components in preprogrammed systems. Customized Building Automation System (BAS) controls are commonly required to fully integrate all building systems, but this cost and sophistication also provides better system optimization.

Upgrading Existing Commercial HVAC System Controls

As introduced earlier, pneumatic controls were used before digital controls were introduced to the HVAC industry. Therefore, a significant number of older buildings are still using pneumatic controls. The desire to take advantage of the many benefits of digital controls and the fact that some new equipment is only capable of digital communication creates a desire for control upgrades. Control upgrades are also considered in older buildings still using their originally installed DDC controls. Digital technology evolves and outdates; think about your first smartphone compared to the one you use today. These digital advancements also pertain to a DDC system and their software, meaning the control systems must be upgraded to take advantage of the newest and most progressive features. The following items need to be considered when contemplating an HVAC control system upgrade:

- Compatibility and integration with existing and new components

- Verification of communication protocols for all components

- Downtime of the HVAC system during the conversion

- Cost of replacing the control components

- Training of the facilities team on new system controls

Rather than removing and replacing the HVAC controls in their entirety, a controls upgrade can be implemented in phases. Phased implementation can distribute the cost over multiple budget years and reduce the downtime associated with the transition. A common phased upgrade approach is to decide on the desired control capability, purchase the controller and user interface, and then slowly convert to the new system by tying in new HVAC components as they are replaced as part of the system's regular maintenance gradually improving performance and capability.

AAON understands the importance of a reliable controls system. With AAON Xtend you get a complete upgrade path while maintaining AAON’s standard of quality and serviceability. Click Here to learn more about AAON Xtend.

Commercial HVAC Controls – An Evolving Technology

Digital technology is experiencing a significant transformation with the advent of wireless devices, AI, cloud computing, and the Internet of Things (IoT). These advancements are positioning the HVAC industry to enhance system performance by reducing the cost of operation by using real-time data and predictive models to optimize fuel source selection, time-of-day consumption, and system maintenance and service.

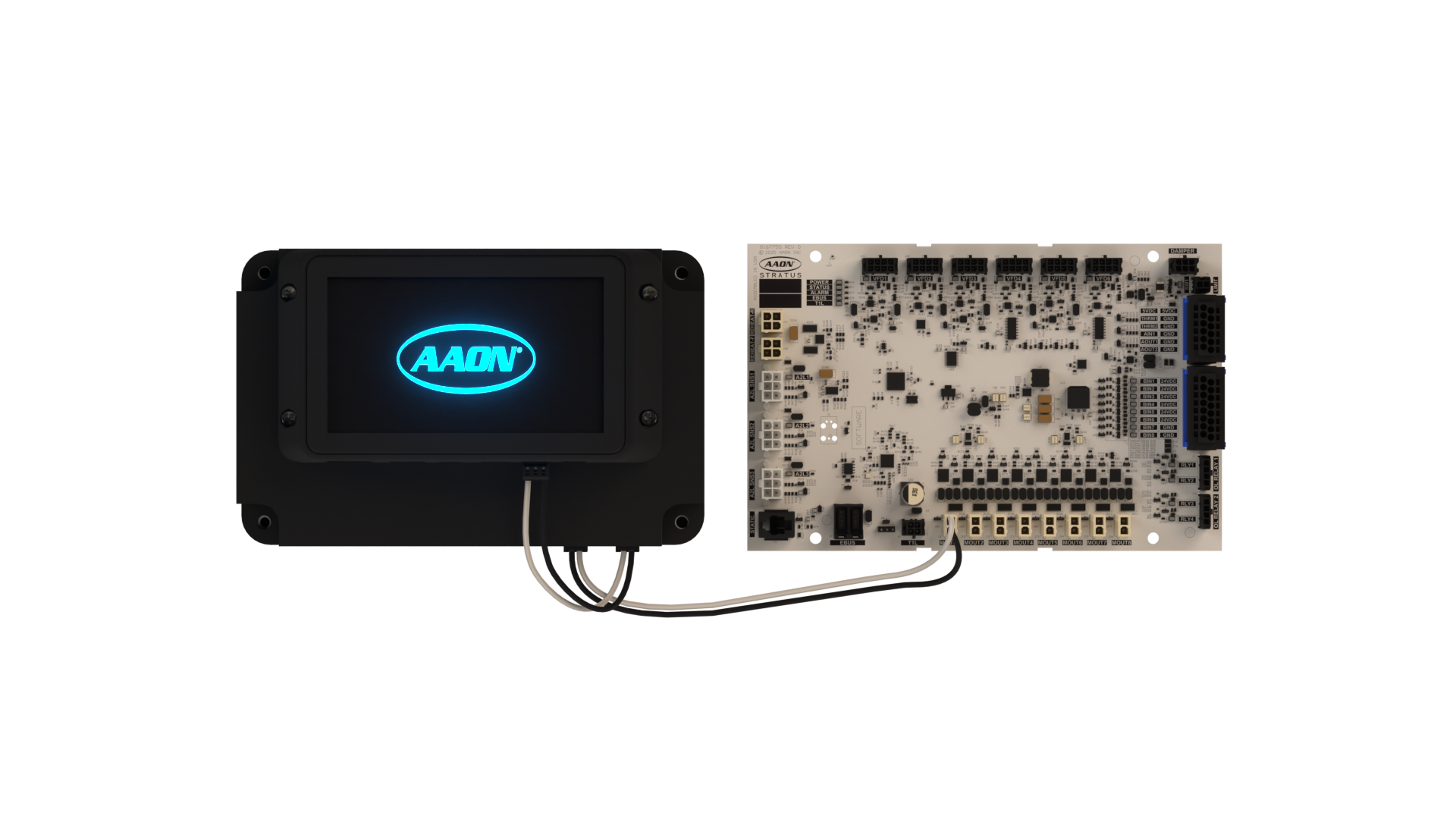

Stratus Controller with Cooling Board

Stratus Controller with Cooling Board

Frequently Asked Questions (FAQs) on Commercial HVAC Controls

-

What are the key components of a DDC HVAC control system?

All DDC control systems consist of 4 elements:

-

Sensor for input

-

Actuator for output

-

Controller for processing and sending commands

-

User interface to monitor and adjust

-

-

How do DDC HVAC control systems work?

Most HVAC control systems have multiple sensors and actuators connected to a single controller. The logic programmed in the controller enables the data collected to be used to change the system operation to provide the desired outcome. The user interface allows users to change the parameters based on their preferences. These four components are contained in a single packaged unit in the simplest of applications. In larger, more complex systems, these components are distributed throughout a building and incorporate multiple units.

-

How do DDC HVAC control systems improve energy efficiency?

HVAC control systems decrease energy consumption by employing strategies that optimize the system operation to meet the desired space parameters. This can be accomplished through algorithms programmed into the controller that use input from sensors and the user interface to automatically adjust the HVAC devices to meet the needs while using the least amount of energy. Below are examples of just a few of a multitude of automatic control scenarios.

Common of most any commercial HVAC control system is a temperature sensor reporting that the space temperature exceeds the owner-dictated setpoint. The controller receives the space temperature, identifies it as higher than desired, determines the best way to provide this cooling, and sends this signal to the equipment to accomplish this. The controller can monitor the system to decide if it is more efficient to increase the fan speed to deliver more air or maintain the airflow and instead decrease the air temperature delivered to the space.

The HVAC control system can also improve energy efficiency by informing the facilities staff of corrective action when an element of the HVAC system is not performing as it should. Implementing a sensor at the air filter to signify when the pressure exceeds a defined threshold and having the controller notify staff is an example. Without this sensor and notification, a dirty filter would require more fan energy use than required.

The user's ability to interact with the HVAC control system to program occupancy schedule and the incorporation of occupancy sensors allows the system to adapt to different setpoints for nights or weekends when the building is empty, and to gradually adjust temperatures before the building’s occupants arrive leading to greater comfort without wasting energy.

HVAC controls are critical to optimizing energy savings in buildings.

-

What are the benefits of upgrading to a Building Automation System (BAS)?

Building Automation System (BAS) controls incorporate building system control beyond HVAC, such as lighting, security, and life safety. The significant advantage of a Building Automation System (BAS) is its ability to share information between systems to streamline both first cost and operation.

-

What items should be considered when selecting a commercial HVAC control system?

When deciding between commercial HVAC Controls - unit level controls, controls that are limited to only the HVAC system, or implementing a Building Automation System (BAS) that is customized to control multiple systems - the budget, the function of the building, the type of HVAC system, and the targeted level of optimization must be considered.

-

What maintenance is associated with a commercial HVAC control system?

HVAC control systems require maintenance like any other system in a building. The most consuming maintenance items are the input sensors and the output devices, since many of these are distributed throughout the building. Most sensors and actuators require regular calibration, cleaning, and physical inspection for damage to ensure the values provided to the controller or actions in response to the controller are accurate. The controller will require regular software updates, as experienced with any computer. It is also important to routinely verify system functionality, as it is possible for a system failure, whether a component failure or communication error, to go undetected for some time. The result can be increased energy use or unnecessary strain on other system components, compromising system longevity and ultimately increasing costs due to premature replacement.

Have Questions About HVAC Controls?

Your local AAON representative can help you find the right control solution for your building’s needs.

Click Here to get in touch.