Multi-zone VAV systems and their Applications

What is VAV in HVAC

Understanding Variable Air Volume (VAV) Systems

A variable air volume (VAV) system adjusts the amount of air delivered by a fan to condition (heat or cool) a space based on demand. This can be accomplished in either a single zone or multi-zone application. The units primarily utilize air conditioning in cooling mode.

In nearly all HVAC systems, the amount of heating and cooling required to maintain desired space conditions are variable. There are many factors that fluctuate impacting the heating and cooling load: envelope load (outdoor air temperatures and construction materials), solar load (sun position and shading), and internal loads (the number of people and their activity, the operation of heat producing equipment, lights, etc.). The system is sized for the peak (worst design case) heating and cooling load, but if the system were to operate at these peak capacities all the time, the space would be excessively heated or cooled.

HVAC systems can address this variability in one of three ways:

-

Constant Air Volume / Constant Temperature (CV/CT),

-

Constant Air Volume / Variable Temperature (CV/VT),

-

Variable Air Volume / Constant Temperature (VAV/CT).

This definition focuses on the third and commonly applied option, VAV, because of its many benefits.

Questions? Our experts are here to assist you.

Contact your AAON representative today.

👉 Find a Rep

How Does a Variable Air Volume (VAV) System Work?

Efficient variable air volume systems were made possible through the introduction of variable frequency drives (VFDs) and have become the industry standard today. A VFD controls the speed of a fan altering the amount of air distributed. When a space experiences part-load conditions, rather than turning the system off or changing the delivery air temperature as done in a constant volume system, the VAV system reduces the amount air delivered to the space enabling it to save energy while still satisfying occupant comfort and ventilation needs.

Variable air volume systems can be classified into two distinct categories - single zone or multi-zone. Knowing the difference is important because they operate differently and are appropriate for different HVAC applications.

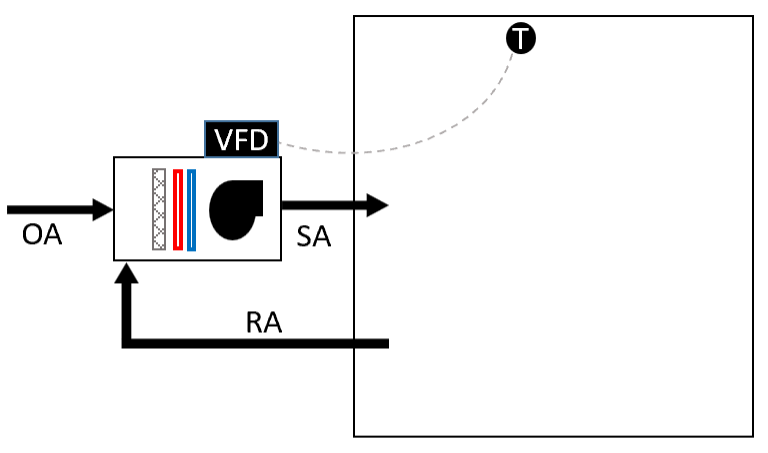

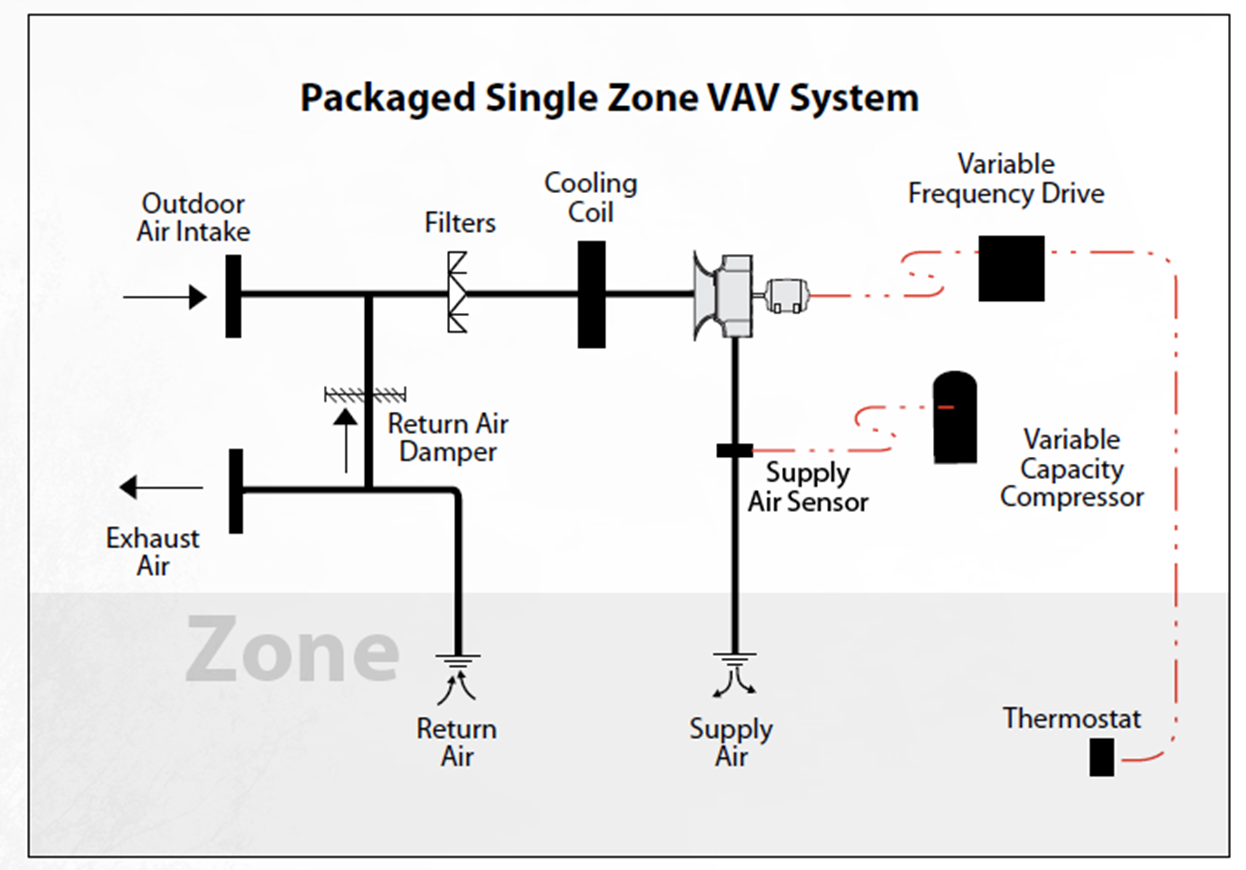

Single Zone Variable Air Volume (VAV) System

Single zone VAV systems utilize a single thermostat to determine the need for heating or cooling. Since the supply air temperature is constant (~55°F when cooling and ~20°F above the room temperature set point when heating), the fan speed is sped up or slowed down based on this temperature setpoint from a sensor in the supply duct. Once the space temperature has been satisfied, the fan will slow down, reducing the air volume and saving energy. In a DX cooling application, the compressor(s) can stage up or down to maintain the desired air temperature also reducing energy use. For example, if the supply air temperature goes below 55°F, the compressor will start to stage down. Because there is only one thermostat per unit, if multiple spaces are being cooled from one unit, the space(s) without the thermostat will likely be more uncomfortable. Commonly, multiple single zone VAV units can be used in larger buildings with many rooms, such as schools or offices.

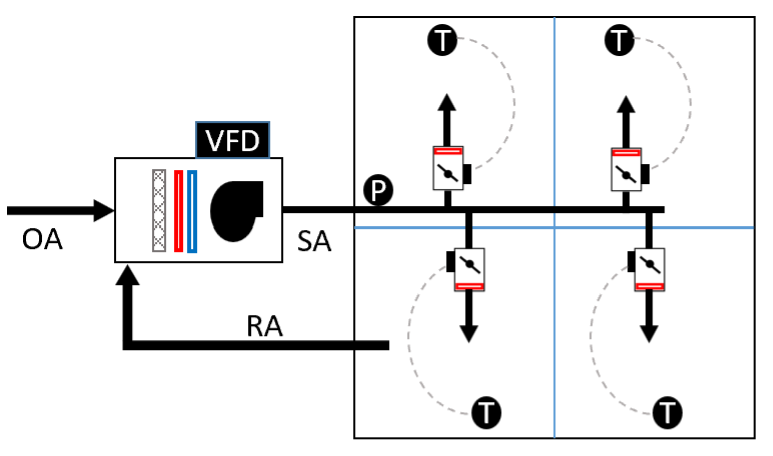

Multi-zone VAV System

For a multi-zone VAV system, a central unit provides air conditioning to multiple spaces, such as offices in a commercial building. Each space, or zone, has what is called a VAV terminal or VAV box. There are several different VAV boxes that can be selected based on application: single duct, dual duct, or series fan-powered VAV terminals. Single duct and fan powered VAV systems are the two most common systems, where a single duct system uses one supply duct system. Other systems not as common would be a dual duct system, however they are not as common due to the expense in additional supply duct materials.

The VAV box utilizes a damper that will open or close based on a thermostat demand. If the space temperature rises above the thermostat setting, the damper will open to allow more airflow into the zone. Once the thermostat sends a signal indicating the space temperature is satisfied, the dampers will close to a minimum position to allow for ventilation. As dampers in the zones open and close, the static pressure in the ductwork will change. The supply fan will modulate based on the static pressure value, which is provided with a static pressure sensor. A defined static pressure range is set based on the application. For example, if the static pressure drops below the setpoint, the fan will speed up. This will happen due to the VAV dampers opening. This control of the fan can lead to increased fan energy savings for the unit.

In the heating seasons, sometimes a space may need a little heating. VAV boxes can be equipped with electric heat strips or hot water coils to control the heating into the space. It is rare that all zones will need heating so it does not make sense to control the heating at the central unit for a multi-zone setup.

Key Components of a Multi-Zone VAV System

Since multi-zone VAV boxes cannot provide cooling at the zone level, a central unit is required to produce the cool air. This central unit could be a direct expansion (DX) or chilled water air handling unit or rooftop unit. Within the multi-zone system, you have the following key components:

-

Static pressure sensor: used to control the supply fan speed.

-

Supply air temperature sensor: used to control the compressor modulation (if a DX system) or chilled water valve (chilled water system).

-

VAV boxes: controls the amount of airflow delivered to the space.

-

Thermostat: used in each zone to control the VAV box damper position.

To optimize the system operation, reduce energy use, and to conform with the energy codes, sophisticated HVAC system controls are needed for multi-zone VAV systems. These direct digital controls (DDC) ensure precision of airflow delivered to the space.

Benefits of Using Multi-Zone VAV Systems in HVAC

Multi-zone VAV systems are most commonly selected for their ability to provide simultaneous heating and cooling within the same building using a centralized unit. The ability to provide greater occupant control and comfort is a wonderful benefit to this system but there are other positive attributes that should not be overlooked.

The use of a centralized unit allows consolidated maintenance because this unit contains the fan, filters, and coils. This eliminates the need to interrupt or schedule maintenance around the occupant and reduces maintenance time of facility personnel compared to a distributed system. Although there are VAV terminals dedicated to each zone throughout the building, these are basic units requiring minimal maintenance. Utilizing a computerized maintenance management system (cmms) can help leverage proper maintenance schedules for servicing the system.

When dampers in VAV terminals reduce the air delivered to spaces from the central unit in response to zone loads, the total amount of cool air produced by the central unit decreases. Since fans are the most significant consumer of energy in many HVAC systems, VAV systems are a very good solution for applications prioritizing comfort, reduced energy use, and sustainable design.

Lastly, but certainly not less important, is the constant lower air temperature produced by the VAV system. This provides better dehumidification at part load conditions compared to constant volume systems. This is significant because high humidity can result in decreased indoor air quality and introduce the potential for mold growth; not only decreasing comfort but possibly compromising occupant health.

Challenges and Considerations

Proper design and installation are always priorities with any HVAC system. However, with VAV systems, especially multi-zone, zoning and ventilation are especially important. Factors such as understanding building layout and orientation, occupancy schedules, zoning of the spaces, and thermostat placement all become critical for ensuring maximum comfort and energy efficiency. Ventilation is just as important in a VAV system as other HVAC systems. Airflow reduces as zone heating/ cooling demand decreases, but the amount of air delivered to a zone cannot go to zero when it is occupied due to ventilation requirements. Calculation that can be complex are needed to determine how the system will efficiently function with the fluctuations in airflow. Sometimes, it is easier to pair a dedicated outdoor air system (DOAS) with a multi-zone VAV unit to control the ventilation necessary.

Noise levels in a space can be an important factor for the design of the system. Placing VAV boxes above unoccupied spaces with branch ductwork to the space can help limit noise in the space. in some cases the VAV boxes may produce some air noise as the damper opens and closes. Noise reducing upgrades can be made for the VAV boxes to ensure a quieter operation and create less disturbance to occupants in the space.

Space availability and coordination are both attributes of a multi-zone VAV system that cannot be ignored. Using a large, centralized unit to deliver air to many zones requires large ductwork to be connected to the unit and distributed in the ceiling plenum. When a central unit is located inside the building, a mechanical room large enough to house the unit with adequate space to service the equipment is needed. In larger applications, the use of multiple central units to serve a single building may be preferred when considering the space available, the building use schedule, and the desire for reduced risk in case of failure. Using multiple central units can also contribute to greater energy savings.

VAV Solutions from AAON

Recognizing the many benefits of multi-zone VAV systems, AAON has addressed the two most common barriers associated with this system – lack of interior space for the central unit and the cost of customized controls. Not having space for an interior mechanical room to house a traditional air handling unit (AHU) as the central cooling unit commonly eliminates multi-zone VAV from consideration as a system option. In the past, the only way around this was to upgrade an AHU to have an expensive weatherproof enclosure or to build a penthouse to enclose the unit. AAON’s packaged rooftop units (RTUs) provide a better and more cost-effective solution.

AAON’s RTUs are designed to be placed outdoors, arrive as a packaged piece of equipment simplifying installation, and their customizable selection allows it to perform as the central unit even under the most unique conditions. Not only can an AAON RTU be used as the central unit, but AAON can integrate multi-zone VAV controls. Integration of AAON controls reduces first cost compared to other systems. This allows multi-zone VAV to be a solution in applications where it was cost prohibitive in the past. AAON utilizes advanced integrated controls to also eliminate the need for expensive, overly complicated BAS/BMS systems. Besides the cost savings of integrated controls, the start-up process is streamlined by not having to coordinate between multiple vendors. Add the energy savings that occur over the life of the building because central unit performance is optimized with integrated controls, it becomes clear that AAON has provided a complete cost competitive solution.

These same controls can also be integrated into other AAON equipment when used as the central cooling unit in a multi-zone VAV system. AAON AHUs provide best-in-class flexibility whether considering indoor units, outdoor units, packaged units or split units. With the many features available with an AAON unit and the ease of customization, AAON can meet the specific needs of any building while providing assurance that both superior value and performance are attained.

Frequently Asked Questions (FAQs) About VAV in HVAC

What is a multi-zone VAV system in HVAC?

Multi-zone VAV is a type of HVAC system that varies the airflow to different rooms or groups of rooms in a building based on its heating or cooling needs.

How does a multi-zone VAV system work?

A multi-zone VAV system employs a control system to monitor the space needs and adjusts the airflow to the space from a central unit and air temperature using a VAV terminal. The central unit delivers cool air to all the zones in the building and the VAV terminal dictates the amount of air that is delivered to the space. When the zone thermostat indicates cooling is needed, the damper within the VAV terminal is opened and cool air is delivered. As the cooling demand decreases, the VAV terminal damper is closed to reduce the amount of cool air delivered. When the space is occupied, the damper will have a minimum airflow set point to ensure adequate ventilation air is provided to the space. If the space temperature is too cold with minimum air flow, the heating coil in the terminal unit is activated to satisfy the desired space conditions.

As each zone’s VAV terminal adjusts the amount of air delivered to the zone in response to the thermostat, the quantity of air that the central unit needs to supply to the system varies. The fan in the central unit utilizes a VFD to adjust the amount of air delivered based on the cumulative system demand from the zones. The response of the central fan to the variable demand for airflow at the zones allows fan energy to be conserved.

What are the benefits of a VAV system?

-

Precise temperature control: Allows independent zoning of spaces for optimal comfort.

-

Responsive: Ideal for buildings with different exposures, varying occupancy, or changing usage patterns.

-

Lower fan energy consumption: Modifying the fan speed at the central unit when dampers in the VAV terminals reduce airflow saves energy.

-

Centralized maintenance: Having the fan, cooling coil, and filters in single centralized location decreases the time required to service the system.

What are the components of a multi-zone VAV system?

The system at minimum consists of:

-

A central unit housing a supply fan, coil(s), and filters: This unit conditions and distributes cool air to each zone VAV terminal.

-

VAV terminal (VAV box): Zone level unit containing a damper that regulates airflow in response to space conditions. In most cases, this unit also has a heating coil to modify the air delivery temperature.

-

Ductwork: Provides an airpath between the central unit and VAV terminals and from the terminals to the space.

-

Controls: Sensors, actuators, thermostats, etc. are digitally integrated to ensure the system provides the desired conditions to each of zones while not using more energy than necessary.

What are the different types of VAV terminals used in a multi-zone VAV system?

- Single-Duct VAV: Modulates the amount of cool air from the central unit to the zone.

- Single-Duct VAV with Reheat: Most common of the terminal units. A heating coil is added to the single duct VAV allowing heating to also occur at the zone.

- Dual-Duct VAV: Hot and cold air from separate ducts are regulated at the terminal allowing for precise temperature control. Rarely used due to the extra expense associated with two supply air ducts.

- Parallel Fan-Powered VAV: A fan is added to the single-duct VAV. Rarely used due to the extra expense associated with two supply air ducts. The fan is positioned to the side of the unit and does not operate unless the central fan is turned off and heating is needed. Primarily used in perimeter zones in cold climates.

- Series Fan-Powered VAV: A fan is added to the single-duct VAV but operates any time the space is calling for less than 100% design cooling airflow. As the terminal damper closes to reduce cool air from the central unit, the fan draws air from the space and mixes it with the cool air to ensure space comfort. This unit allows constant air flow to the zone.

How is a multi-zone VAV system different from a single zone VAV system?

-

Single Zone VAV System: Adjusts fan airflow to maintain the defined space conditions.

-

Multi-zone VAV System: Utilizes terminal units to allow multiple zones to be served by a central unit. The central unit cools the air and distributes to the terminal units. The terminal units modulate the airflow and use a heating coil to provide simultaneous heating and cooling to different zones. The fan in the central unit is variable volume in response to system demand.

Both VAV systems save fan energy, whereas the multi-zone provides better zone control.

What challenges are associated with multi-zone VAV systems?

-

Initial costs: Higher installation costs compared to simpler HVAC systems especially attributed to controls.

-

Ventilation: Maintaining proper ventilation without incurring extra expense by over ventilating some of zones requires complex calculations and significant design time.

-

Space: Requires space for a larger central unit as well as longer duct runs and terminal units.

-

Noise control: Proper design is needed to minimize noise from fan powered VAV terminals.

Why choose AAON for multi-zone VAV systems?

AAON has addressed the two most common barriers associated with this system – lack of interior space for the central unit and the cost of customized controls. AAON RTUs be used as the central unit with AAON’s integrated multi-zone VAV controls. Integration of AAON controls reduces first cost compared to other systems. This allows multi-zone VAV to be a solution in applications where it was cost prohibitive in the past.

These same controls can also be integrated into other AAON equipment when used as the central cooling unit in a multi-zone VAV system. AAON AHUs provide best-in-class flexibility whether considering indoor units, outdoor units, packaged units or split units. With the many features available with an AAON unit and the convenience of customization, AAON can meet the specific needs of any building while providing assurance that both superior value and performance are attained.

Connect with an AAON rep to learn how our multi-zone VAV solutions could be the right fit for your project.

👉 Find a Rep Near You