Plenum Fan: Comprehensive Guide

Plenums are found in commercial HVAC applications, typically located in the ceiling in the form of sheet metal plenum boxes. It operates like a hub for air distribution, connecting the HVAC system to the ductwork.

ASHRAE defines Plenum as the following:

"Plenum -(also called plenum box and plenum chamber) (1) a compartment or chamber, to which one or more ducts are connected, that forms a part of the air-distribution system and that is not used for occupancy or storage. A plenum often is formed in part or in total by portions of the building. (2) an air compartment that is attached to, or is an integral part of, a forced-air furnace which is designed to either distribute the heated air after it leaves the heat exchanger in the case of a supply plenum or to collect air that enters the return inlet in the case of a return plenum. (3) component forming an interface between a ductwork and one or more air terminal devices, by virtue of its design or by the inclusion of accessories, it can also be used to equalize the pressure/velocity across the air terminal device."

What is a Plenum Fan?

ASHRAE defines Plenum Fan as the following:

"Plenum Fan - fan assembly consisting of a single inlet impeller mounted perpendicular to airflow that pressurizes a plenum chamber in an air-distribution system. The impeller is typically an airfoil or backward-inclined design."

These are unhoused fan designs within the air handling section of a HVAC system. They may also be called interchangeably with plug fan.

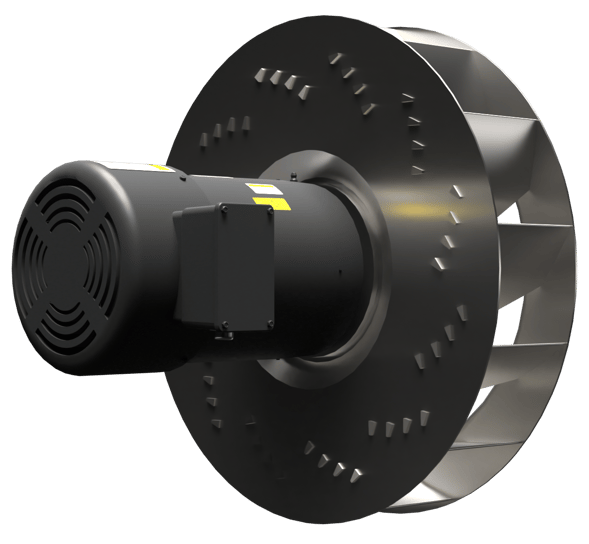

Backward Curved Plenum Fan

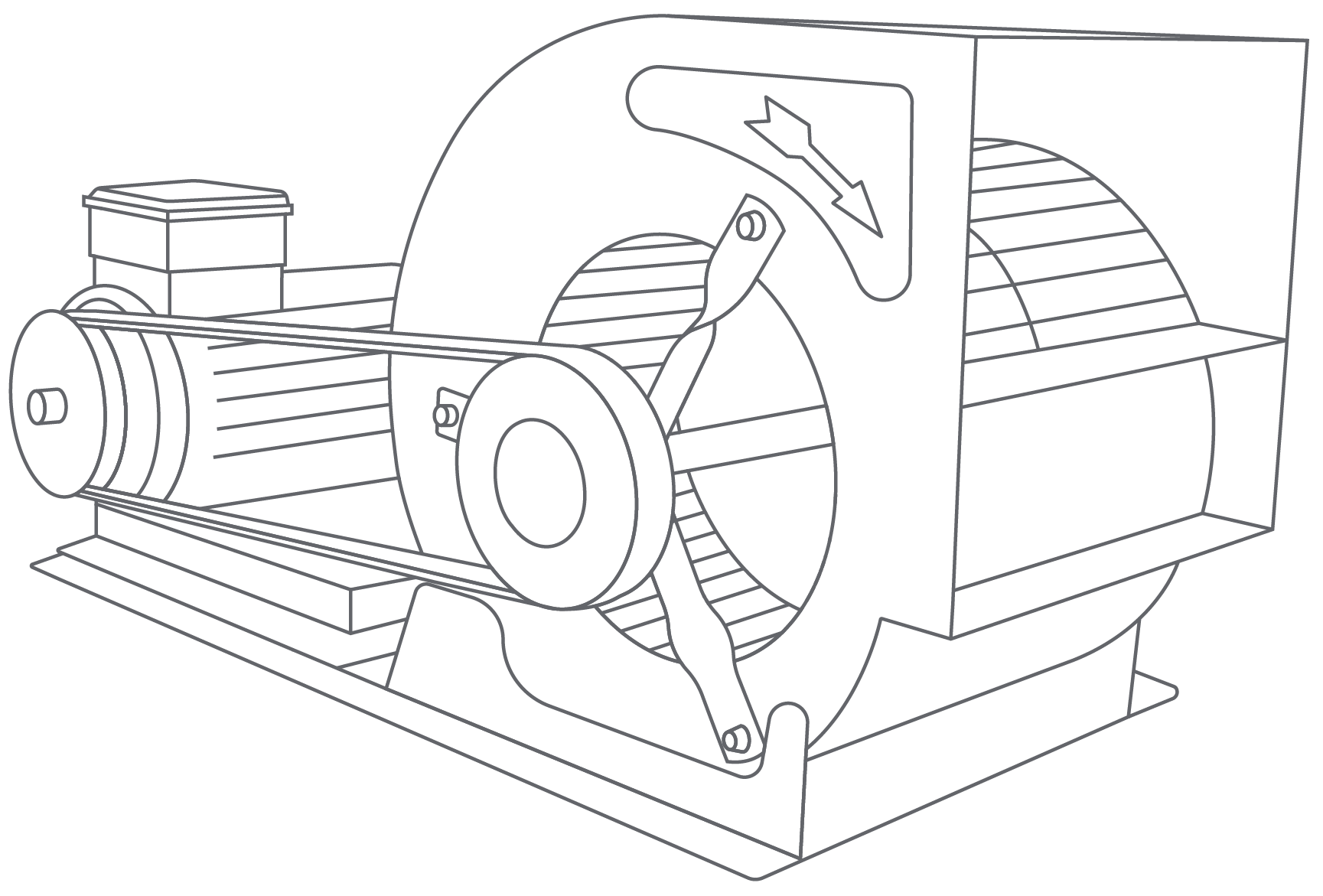

Housed Centrifugal Fan

Differences Between Plenum Fan and Housed Centrifugal Fan

Plenum Fan vs. Housed Centrifugal Fan

Design

Plenum fans will have no scroll housing, discharging air freely into the plenum space. It is an open design allowing the fan to rely on the plenum space for distributing air rather then directing it into a shaped outlet.

In contrast, housed centrifugal fans are designed inside an spiral scroll housing. The housing will collect the air from the wheel and channel through its outlet. The scroll shape design assists with converting the velocity into static pressure.

Plenum fans may come installed alone in the HVAC system or incorporated into fan arrays. The Plenum fan's compact and modular nature makes it a more flexible option layout wise for air handling units, particularly in conditions with limited space.

Both fans can use different fan types, such as:

-

Backward Curved

-

Backward Inclined

-

Airfoil

-

Forward Curved

Motor Type

Plenum fans are typically direct-driven designs. This is where the fan wheel is mounted directly to the motor shaft. Direct drive designs eliminate belt losses, can improve efficiency, and reduce maintenance requirements involved with belts. Direct-drive configurations often have precision speed control offered by the VFDs controlling it.

Housed centrifugal fans more commonly are belt-driven systems. Belt drives have the benefit of allowing adjustment of fan speed by changing pulley sizes, making them useful for in field tuning. However, repair and maintenance for belt-driven systems requires more time. Belt losses average 3-8% of total energy of the fan.Learn more about the benefits of direct drive fans here.

Efficiency

Efficiency differences largely depends on the fan’s mechanical configuration and even blade style. Plenum fans often will have higher system efficiency because they commonly use direct-drive motors. When paired with a backward curved fan type, they can provide excellent energy performance, particularly in variable-air-volume (VAV) systems.

Applications of Plenum Fans

-

HVAC systems in commercial buildings

Plenum fans are widely used in office buildings, schools, and hospitals where variable-air-volume systems are more common. Their compact size and quiet operation make them ideal for these types of applications.

-

Industrial air handling units

Plenum fans offer flexible installation and can be engineered into fan arrays to meet high airflow demands with built-in redundancy in large manufacturing or processing facilities.

-

Cleanroom and data center environments

Facilities required to maintain precise airflow control, redundancy, and energy efficiency often prefer plenum fans. Fan arrays ensure stable performance even if one module fails, which is essential for critical-environment reliability.

Advantages of Using Plenum Fans

-

Improved energy performance at part-load conditions

Plenum fans pair very well with variable-frequency drives, allowing them to reduce speed efficiently when the system demand drops. Because they don’t rely on belts and don’t need to overcome scroll-related pressure effects, they typically maintain higher efficiency during turndown compared to housed centrifugal fans.

-

Space-saving design

Plenum fans are typically smaller and offer more mounting flexibility than housed centrifugal fans. Their modularity supports more compact AHU designs, increased access space, or additional filtration and coil sections. Housed fans typically need much more space after the fan as the discharge velocity leaving a housed fan is very high.

-

Improved sound attenuation

The surrounding plenum often serves as an acoustical buffer. Without a scroll concentrating noise at the discharge, plenum fans tend to operate more quietly, especially when arranged in multiple smaller modules.

Frequently Asked Questions

What is a plenum in an HVAC system?

A plenum is an enclosed space within an HVAC system used to distribute or collect air. It often connects directly to the supply or return air ducts and plays a critical role in airflow management and system efficiency.

What is a plenum fan?

A plenum fan is a type of fan installed within a plenum chamber that delivers air directly into the space without traditional ductwork. It allows for flexible airflow distribution and is commonly used in commercial air handling units.

What is the difference between a plenum fan and a housed centrifugal fan?

The key difference lies in design and airflow. Plenum fans operate without scroll housings and discharge air in all directions, making them quieter and more space-efficient. Housed centrifugal fan typically include a housing and provide more directional airflow.

What is the advantage of using a plenum fan?

Plenum fans offer benefits such as quiet operation, reduced system resistance, compact installation, and better airflow distribution, especially in fan array configurations or where there is limited space.

Where are plenum fans typically used?

Plenum fans are commonly used in commercial HVAC systems, cleanrooms, data centers, hospitals, and other spaces requiring quiet and efficient airflow delivery.

Can plenum fans reduce noise in HVAC systems?

Yes, plenum fans generally produce less noise due to the absence of scroll housings and the ability to discharge air over a wider area, which reduces turbulence and vibration.

Is a plenum fan more energy-efficient?

Plenum fans can be more energy-efficient in specific designs where lower system resistance and fan arrays reduce energy consumption and improve airflow control.

How do I choose the right fan?

Consider factors like space constraints, airflow direction, noise requirements, and maintenance accessibility.

Source: ASHRAE Terminology (https://terminology.ashrae.org/?letter=P)

Need assistance?

Your local AAON rep is ready to help.

👉 Find a Rep