Low GWP Refrigerants – A Guide to Sustainable Cooling

What is a Refrigerant?

A refrigerant is a heat transfer medium specifically used because of its property characteristics. A refrigerant changes state between a liquid and a gas as a result of altered temperature and/or pressure. In the process of changing state from a gas to a liquid, the refrigerant absorbs heat which is a critical action in the cooling process.

What is a Low Global Warming Potential Refrigerant?

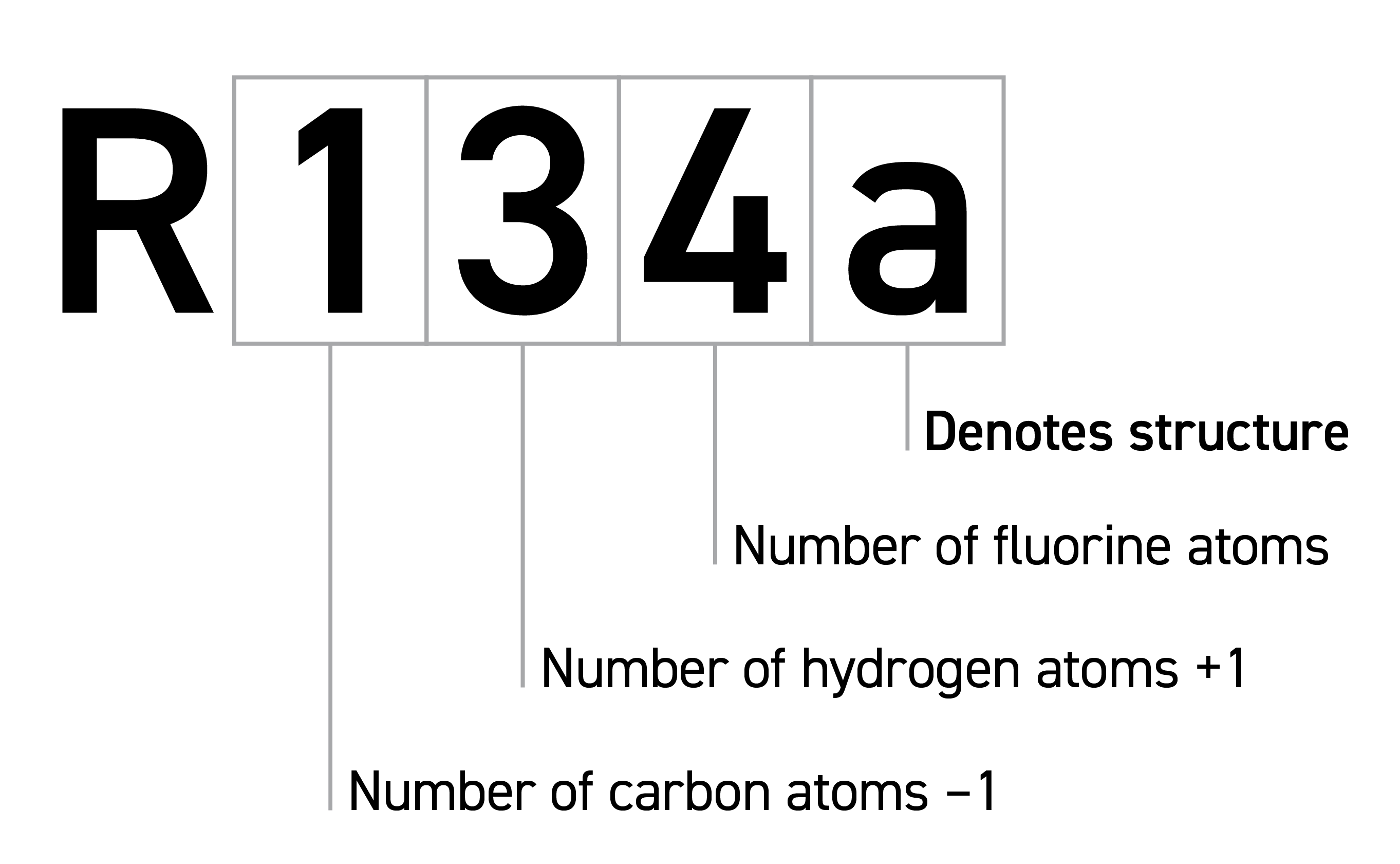

HFC refrigerants – R410A, R407C, have been used as the primary refrigerants in HVAC applications for nearly the past two decades. As these refrigerants’ impact on the environment were explored, a new concern was identified. They possess a high global warming potential also referred to as GWP. GWP is an index describing a refrigerant’s relative ability to trap radiant energy compared to CO2 over a period of time (100 years being the common reference). The higher the GWP value, the more that particular refrigerant warms the Earth compared to carbon dioxide. Each refrigerant is assigned a GWP value that can be referenced when comparing options. As a result, refrigerants are now compared and rated based on their GWP.

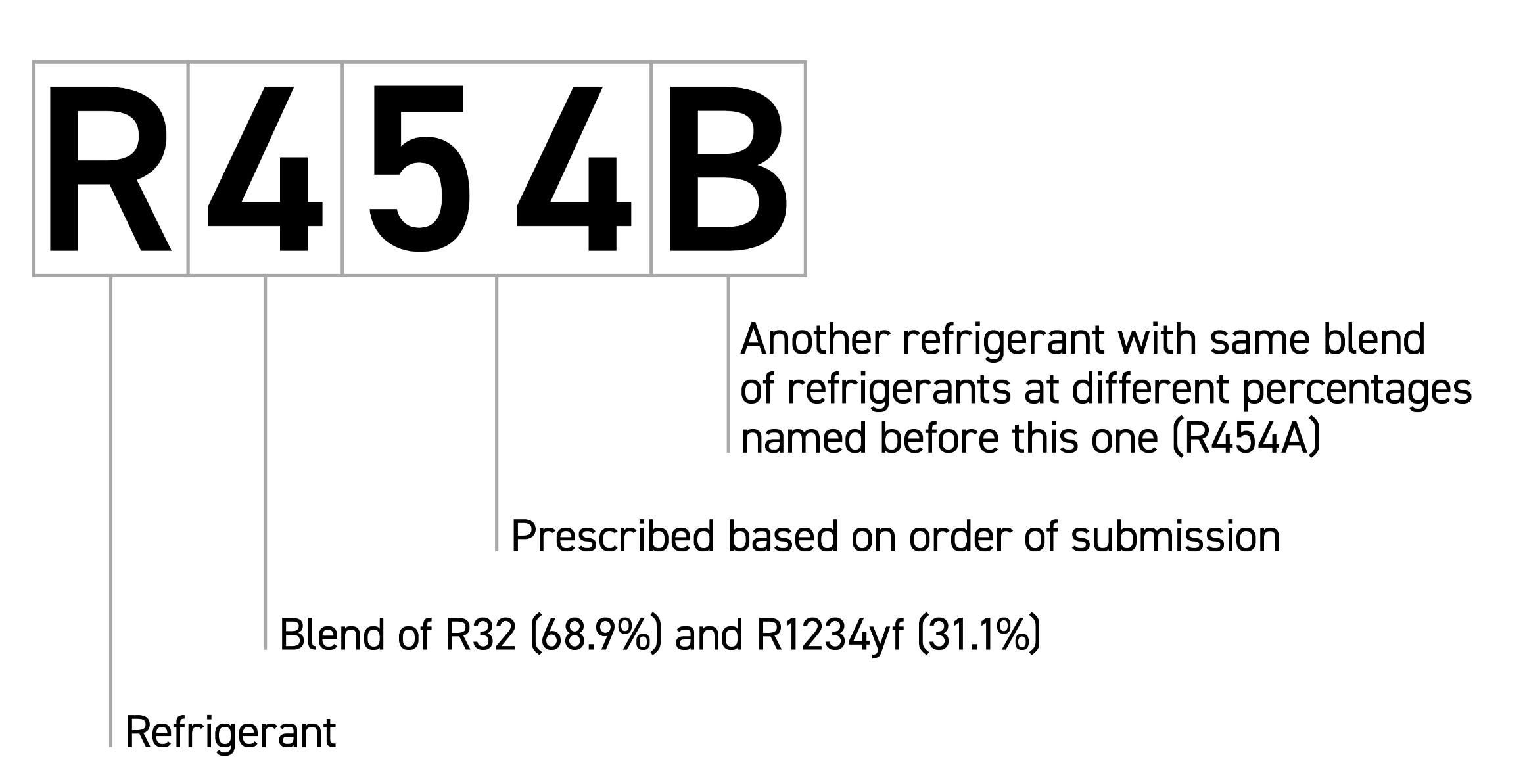

Research and development to find better and more environmentally friendly refrigerants became a priority with reduced GWP as the focus. Although it is an evolving threshold, low GWP is defined as refrigerants possessing a GWP value below 700. The most common alternative refrigerants used in HVAC applications that fit the low GWP classification include the R32 and R454B. R454B achieves its lower GWP value by being a blend of two refrigerants, R32 and R1234YF. R1234YF is classified as a Hydrofluoroolefins (HFO) and is frequently used in automotive air conditioning.

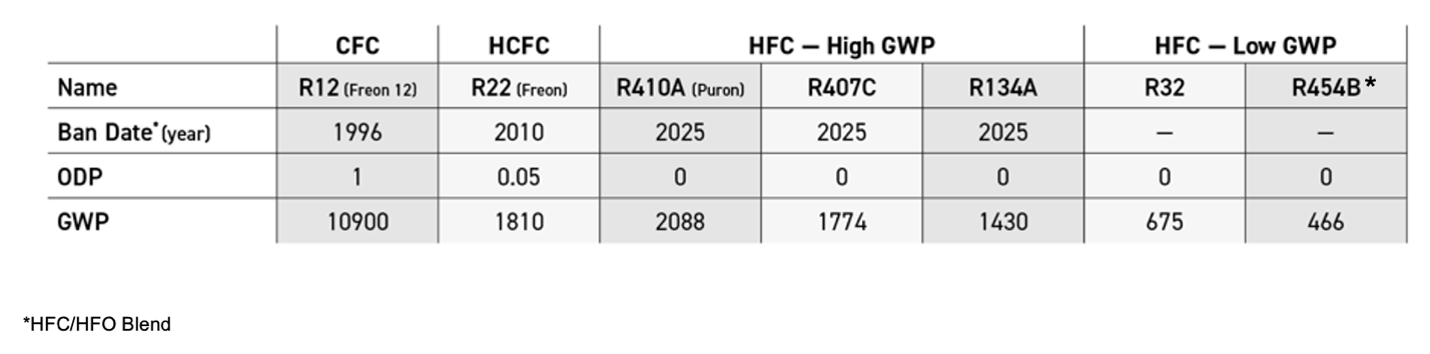

Refrigerants availability has evolved over time as their environmental impact was better understood. The table below compares the most common refrigerants used in building HVAC applications over time and the progression toward more environmentally responsible solutions. The left side of the table begins with the older refrigerants and progresses to the newest of the refrigerants on the right. Both the ozone depletion potential (ODP) and the GWP ratings are also listed for comparison.

Why Do Low GWP Refrigerants Matter?

Increased greenhouse gas emissions (GHGs) have been identified as contributing to climate change because they trap heat in the Earth’s atmosphere. GHGs include carbon dioxide (CO2), methane (CH4), nitrous oxide (N2O), ozone, and fluorinated gases – mainly HFCs. Since the most used refrigerants in HVAC applications are HFCs, a measure has been developed for refrigerants to quantify their GWP. The lower the refrigerant’s GWP, the lower the global warming impact. For this reason, low GWP thresholds have become the target of environmentally focused policies, which have led to new regulations for design and equipment production for HVAC applications.

Low GWP Refrigerants and Regulations

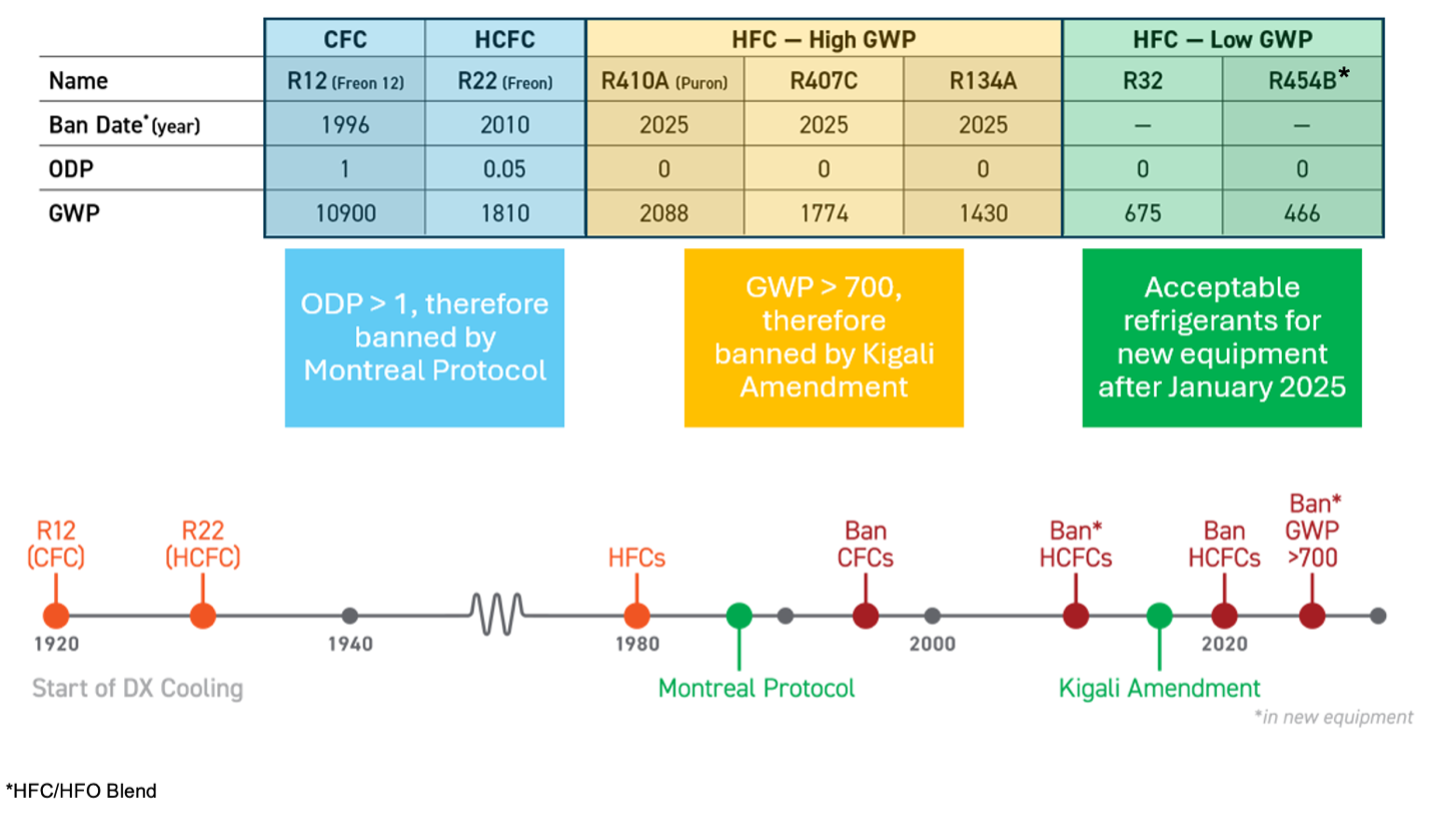

The impact of refrigerants on the environment is a global issue and has resulted in multinational policy making. The first policy was the 1987 Montreal Protocol. It is an international treaty that phased out the use of ozone-depleting substances including CFC and HCFC refrigerants. In the United States, production and importation of CFCs were banned completely in 1996. The Montreal Protocol also banned the production of new HVAC equipment that used HCFC refrigerants in 2010 with a complete phaseout set for 2030. In 2020, HCFC refrigerants could no longer be produced, limiting their availability to recycled or reserved inventories.

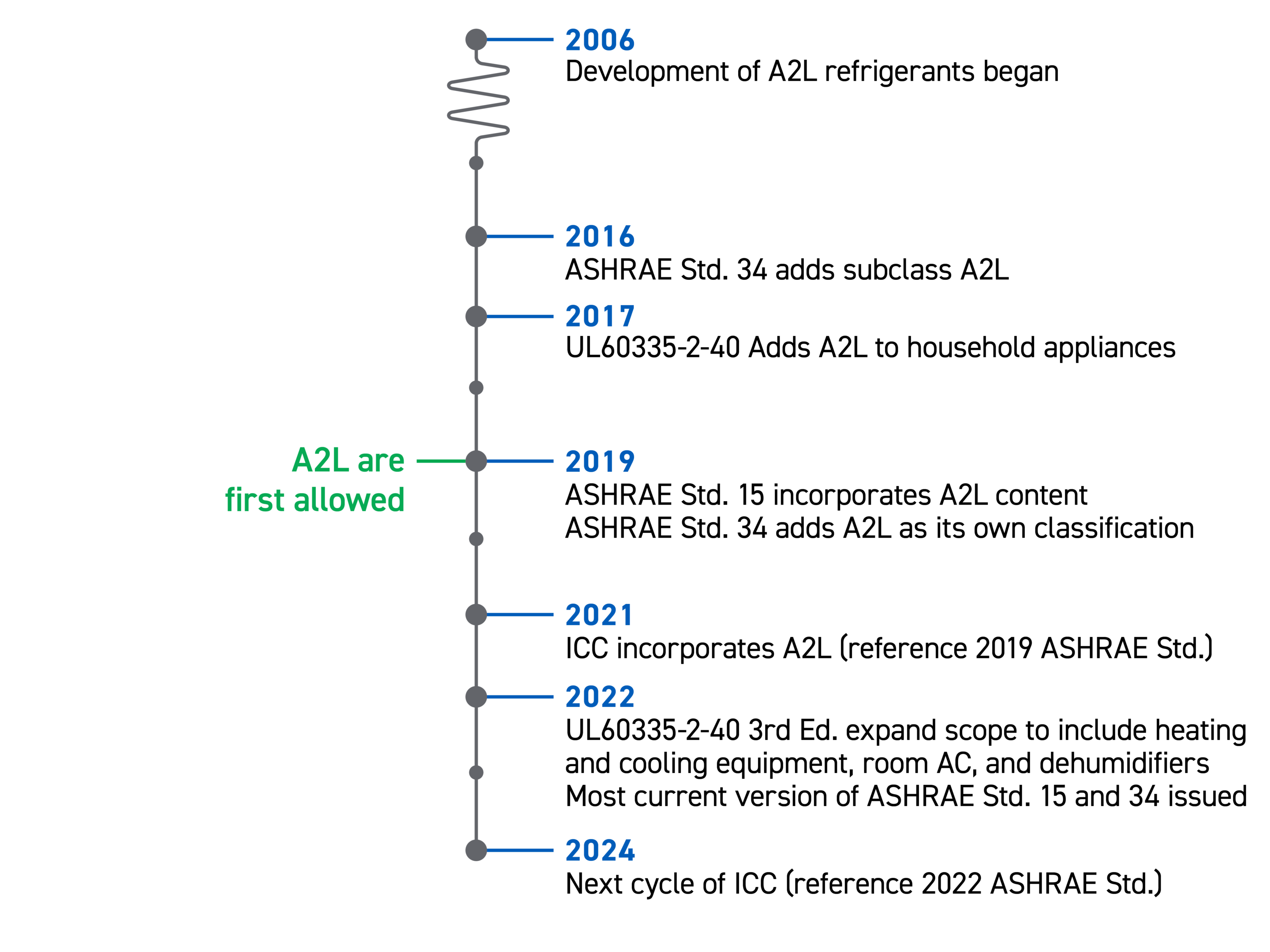

In 2016, the Kigali Amendment to the Montreal Protocol was signed committing nations around the world to reduce the use of high GWP refrigerants and defined phase-down schedules for HFC refrigerants. In the U.S., the environmental protection agency (EPA) started the refrigerant transition by issuing a rule that banned refrigerants with a GWP greater than 700 for most new HVAC equipment production beginning January 1, 2025 (with a few specific equipment exceptions extending to 2027). It can be anticipated that the 700 GWP threshold value will be reduced further in time as lower GWP HFCs are developed, but for the foreseeable future the industry is transitioning to R32 or R454B for all new HVAC equipment.

Challenges in the Transition

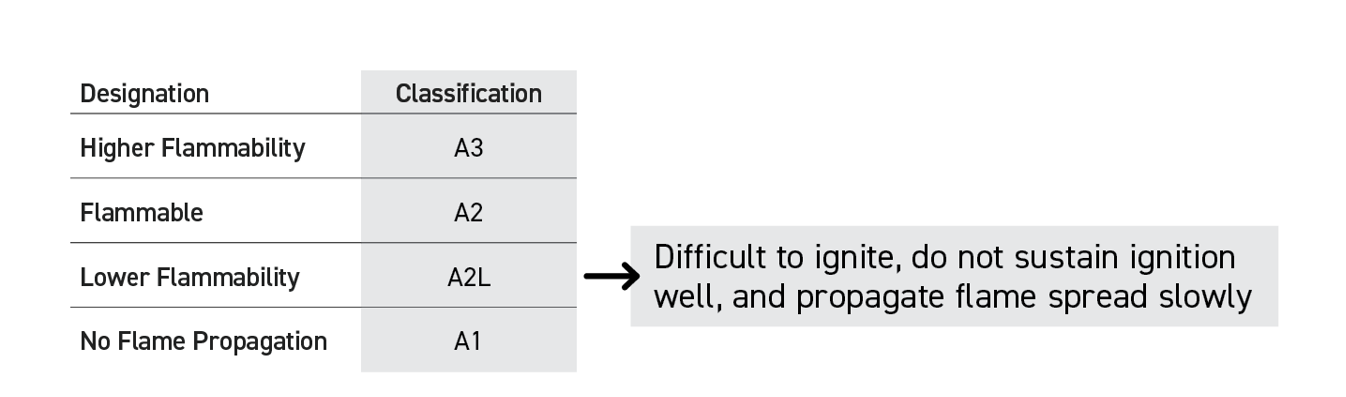

Refrigerants with a low GWP (less than 700) and having an ozone depletion potential equal to zero require a concession – increased in flammability. The most popular refrigerants (with high global warming potential exceeding 700) used in commercial HVAC equipment in the past were classified as A1. ASHRAE Standard 34 identifies A1 classified refrigerants as non-toxic by the ‘A’ designation and non-flammable by the ‘1’ designation. This designation required very few precautions or extra measures be taken in the design and construction of buildings when refrigerant was used. The new low GWP refrigerants R32 and R454B, although still nontoxic, are more flammable, changing their classification to A2L. This classification was created specifically to enable a new threshold of flammability that is capable of being ignited, but the flame propagation is not as extreme as the refrigerants classified as A2. A2L refrigerants are difficult to ignite, do not sustain ignition well, and propagate flame spread slowly. The HVAC industry has devoted the last decade to research and development focused on safe use of A2L refrigerants and the adoption of the A2L classification into building codes.

Refrigerants are addressed in multiple standards and codes as they present a life safety concern. The concern is twofold: direct contact with people and fire.

A refrigerant, if leaked into an occupied space, even if class ‘A’ lower toxicity, can pose a threat to a person. Since the density of refrigerant is greater than that of oxygen, when the volume of refrigerant is great enough within a space to displace the oxygen at the breathing level, affixation can occur.

When using any refrigerant classified with a numerical value other than 1, the potential risk associated with fire is increased. Codes are written to allow the use of these higher risk refrigerants but require that additional precautions be made in the design of the building to ensure that the level of safety is maintained for the occupant.

The three primary model codes pertaining to building design that address refrigerants are the International Building Code, the International Fire Code, and the International Mechanical Code. These codes reference ASHRAE Standard 34 for the refrigerant designation and safety classification and ASHRAE Standard 15 for safety requirements associated with design, construction, installation, and operation of refrigerant systems.

The ICC specifically states that conformance with ASHRAE Standard 15 Safety Standard for Refrigeration Systems is necessary. The topic outlined in ASHRAE Standard 15 that is likely to have the greatest impact on building design with the use of A2L refrigerants is the need for release mitigation controls. These controls detect a refrigerant leak and provide adequate ventilation (to dilute and/or purge) to ensure the safety of the building occupants that may be exposed. The necessary volume of ventilation is determined using the Effective Dispersal Volume Charge (EDVC) calculation defined in the document. Other areas worth also noting are the new maximum limit of flammable refrigerants in a building as well as specific requirements applicable to egress areas such as corridors and lobbies.

Not only does the design community have to be educated on the new refrigerants being used to meet the low GWP requirements, but training and education of those handling and installing these refrigerants is also needed in the industry. These refrigerants have a higher safety risk therefore A2L specific training is required. Training topics focus on safe handling of A2L refrigerants such as their storage and transportation as well as on topics associated with their installation i.e. personal protective equipment (PPE) use, ventilation, leak detection, and leak response.

Transitioning to Low GWP Refrigerants

As the HVAC industry makes the transition to environmentally friendly low GWP refrigerants, there are often questions and concerns related the physical change and economic implications.

Existing HVAC systems may continue to operate as they are. Per the Kilagi Amendment and AIM Act, the manufacture or import of products with HFCs (R22, R410A, R4017C, and R134A ) became prohibited after January 1, 2025. The rule also prohibits the sale, distribution, and export of these products after January 1, 2026. Limitations on the production and import HFCs, concentrating especially those with highest GWP characteristics, began in 2022 with the use of allowances controlled by the EPA. Additional development of rules to phasedown, reclaim, and recycle HFCs are a focus of the EPA. As experienced with the phase out of other refrigerants in the past, the cost of equipment maintenance will increase as a result.

Existing HVAC systems using refrigerants that do not meet the low GWP designation (R22, R410A, R4017C, and R134A) cannot simply be replaced by a low GWP refrigerant (R454B or R32). The DX components within systems have been designed to function with the specific characteristics of a single refrigerant, therefore it will not function properly with an alternate refrigerant.

The transition to new low GWP refrigerants imposes costs that ultimately get absorbed into the price of new HVAC equipment. These expenses are attributed to multiple factors – increased refrigerant cost, increased safety features, component redesign to accommodate new refrigerant characteristics, and recertification. Extensive investments are made in the research and development of new refrigerants as well as the costs associated with the scaling of production of these new refrigerants to meet the increased market demand. Refrigerant detection systems are required in equipment to respond to leaks, resulting in added component costs. Because these new refrigerants operate at different pressures and temperatures than those used previously, expenses associated with HVAC equipment redesign and retooling have to be absorbed. This equipment design change also mandates recertification for compliance with industry safety and efficiency standards which also results in added production expense.

Making the transition to new units using low GWP refrigerants should not only be considered for new applications or replacing a failed piece of equipment, but also to replace existing equipment to future proof your investment and promote sustainable, climate focused technology.

Low GWP Refrigerants in AAON Products

The perfect refrigerant has not been created therefore the selection of the best refrigerant is a balance between different factors including optimizing performance, minimizing the negative impact on the environment, and managing cost.

Performance accounts for the chemical stability, latent heat of vaporization, thermal conductivity, and viscosity of a refrigerant. Each of these factors contributes to the capacity, life, and efficiency of a piece of equipment employing the DX cycle. If the cooling equipment has to be larger to get the same capacity because of the refrigerant’s performance, the customer has to pay for this increased capacity preventing these dollars from being invested in other initiatives. Reduced equipment life because of refrigerant choice does not have an immediate cost implication, but it certainly does over the life of building ownership due to increased frequency of unit replacement. Efficiency is important to the customer as it directly impacts energy bills, but it also needs to be considered as an important part of meeting environmental goals. More energy consumption results in the need for increased power production in turn increasing emissions.

R32 and R454B became the main replacement candidates for R410A. Just as many manufacturers of air conditioners in the U.S., AAON has selected R454B to replace R410A in all AAON products. Both options have similar efficiency to R410A. The two primary reasons for selecting R454B over R32 were related to redesign and GWP. R454B is very similar to R410A making the redesign of units to accommodate this refrigerant less complicated than if using R32. R454B (467GWP) has about 1/3 less GWP than R32 (675GWP), which should allow for a longer useful life as GWPs are lowered over time with the introduction of future environmental policies.

AAON acted as a catalyst for positive environmental change in the HVAC industry by embracing R454B ahead of the regulatory requirements.

Frequently Asked Questions

What are Low GWP Refrigerants?

Low GWP refrigerants are more environmentally friendly chemicals used in the cooling process. They minimize the impact on the environment compared to traditional refrigerants like R-410A or R-134a.

What does GWP mean in refrigerants?

GWP, or Global Warming Potential, is an index describing a refrigerant’s relative ability to trap radiant energy compared to CO2 over a period of time (100 years being the common reference). The higher the GWP value, the more that particular refrigerant warms the Earth compared to carbon dioxide. Each refrigerant is assigned a GWP value that can be referenced when comparing options. Although it is an evolving threshold, low GWP is currently defined as refrigerants possessing a GWP value below 700. The most common refrigerants used in HVAC applications that fit the low GWP classification include the R32 and R454B.

Why are Low GWP refrigerants important?

Increased greenhouse gas emissions (GHGs) have been identified as contributing to climate change because they trap heat in the Earth’s atmosphere. GHGs include carbon dioxide (CO2), methane (CH4), nitrous oxide (N2O), ozone, and fluorinated gases – mainly HFCs. Since the most used refrigerants in HVAC applications are HFCs, a measure has been developed for refrigerants to quantify their GWP. The lower the refrigerant’s GWP, the less it contributes to global warming. For this reason, low GWP thresholds have become the target of environmentally focused policies regulating design and production for HVAC applications.

What are examples of Low GWP refrigerant options in HVAC?

R32 and R454B are the two low GWP refrigerant options used in the HVAC industry. They both have similar efficiency to R410A and significantly lower GWP (R410A: 2088 GWP). R454B (467GWP) is used much more than R32 (675GWP).

What are the challenges of using Low GWP refrigerants?

Low GWP refrigerants are mildly flammable therefore are classified as an A2L refrigerant. This classification mandates increased safety measures be applied. These requirements are defined by codes and new regulations with a primary focus being to identify and quickly to respond to a refrigerant leak through refrigerant detection systems. Building and equipment design as well as training for handling of the refrigerant are affected by this safety requirements.

Low GWP refrigerants possess different chemical properties from refrigerants used previously in HVAC cooling systems. This means that the DX components in new equipment needs to be reengineered for these new performance parameters and production has to be retooled to implement these changes.

Are Low GWP refrigerants safe?

Yes, Low GWP refrigerants are safe when handled correctly and used in conformance with applicable codes and regulations. However, due to being mildly flammable, proper training and adherence to safety guidelines and industry standards are essential for a seamless transition.

How do Low GWP refrigerants compare to traditional refrigerants?

Low GWP refrigerants contribute significantly less to global warming compared to the refrigerants used in the past while maintaining the equipment cooling performance efficiency. Decreasing the contribution of greenhouse gases to the atmosphere, make low GWP refrigerants the obvious choice for more sustainable solution for the future.

Why choose AAON products with Low GWP refrigerants?

AAON acted as a catalyst for positive environmental change in the HVAC industry by embracing low GWP refrigerants and transitioning to R454B ahead of the regulatory requirements. This demonstrates AAONs ongoing commitment to sustainability and innovation. AAON further displays this commitment by not imposing a cost increase associated with the R454B transition to the consumer.